21世紀最大の課題のひとつは、世界のCO2排出量の25%以上を占める従来の輸送手段を脱炭素化することである。脱炭素化は、私たちが近代に期待するようになった相互接続性を犠牲にすることなく行われなければならない。2030年には1億5,700万台のEVが導入されると予想されており、電気自動車供給設備(EVSE)はEVストックと並行して、時にはそれを先取りして進める必要がある。

LEMは、充電ポイントをより信頼性が高く、安全で、手頃な価格で、スマートにする非常に高い技術の電流センサとエネルギー・メーターを供給することで、電気自動車充電インフラの展開に積極的に貢献している。

電気自動車供給装置用途

EVSEの導入を成功させるには、シンプルな充電とエネルギー管理プロセスが不可欠である。この実現には、新技術の導入と、さまざまな用途に適したさまざまな充電技術に対応する強固な規格の一貫した開発が必要である。

さらに、欧州の代替燃料インフラ規制やFit for 55法パッケージのような規制イニシアチブ、米国のNEVIのようなプログラムなど、充電インフラの展開を加速させようとする様々な地域から発せられる重要な指標がある。

これを達成するためには、電流センシング、エネルギー計測、電気安全などの機能を実行する精密で革新的な電気計測技術が必要である。

さらに、円滑な運用を確保するために、インフラには弾力性のある電流センシング技術が必要である。

BEVとEトラックのEV充電技術を理解する

乗用車用バッテリー電気自動車(BEV)の充電オプション

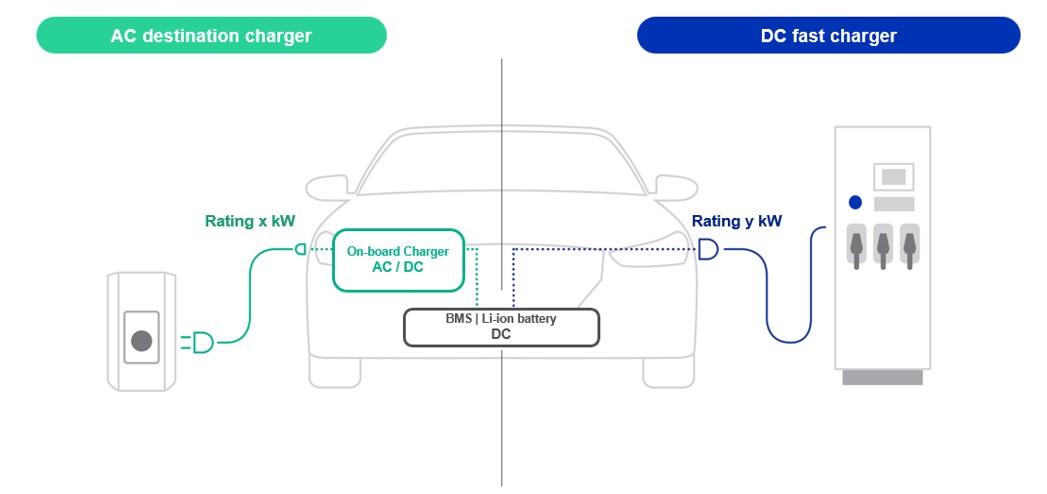

乗用車用バッテリー電気自動車(BEV)の充電は、ACウォールボックス(自動車の車載充電器(OBC)を使用)、または最大充電電力が通常100~250kWの範囲にあるオフボードDC充電器のいずれかを使用して行われる。

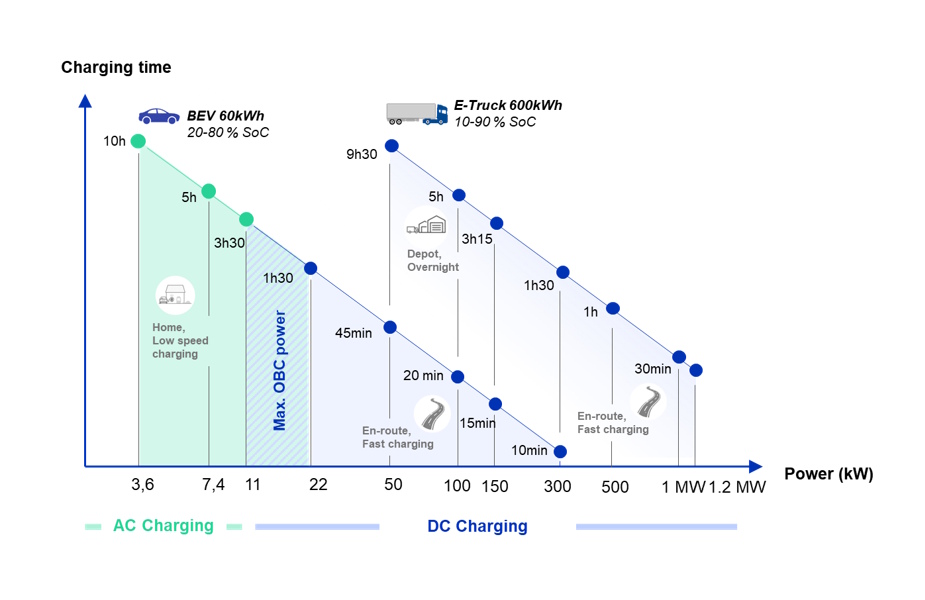

BEV用のAC/DC充電ポイントと出力レベルの選択は、充電可能な時間と希望する充電範囲に依存する。

乗用BEVアプリケーションの場合、AC充電ポイントはほとんどの量を占め、通常家庭や建物に設置される。

BEVの充電方法 - AC充電器とDC充電器

高出力充電器開発のEトラックへの影響

大型車、特にEトラックでは、バッテリーサイズは通常300~600kWhの範囲内である。

オンボードのAC/DCコンバーターによるAC充電を従来の11...22 kWの電力レベルで使用すると、夜間のデポ充電であっても充電時間が過度に長くなる。

したがって、Eトラックの充電は、50kWからメガワットまでのDC充電が主流になると予想される。

BEVとEトラックの充電時間と技術

乗用車用BEVの高出力充電器の開発が進んでおり、直流充電器は400kWまで広く利用可能で、メガワット級まで開発中である。

注目すべきは、4.5時間の走行ごとに45分間の休憩を義務付ける規制である。このような条件下で、標準的な消費量と速度を想定すると、長距離Eトラックの経路充電には700~1000kWの充電電力が必要となる。

AC充電とDC充電の比較: スピード、コスト、利用可能性

便利で広く利用可能な電気自動車供給設備へのアクセスは、運輸部門における電動化への移行の礎石である。

バッテリー電気自動車(BEV)の充電には、BEVの車載充電器(OBC)を利用するか、外部のAC/DCコンバーターをBEVのバッテリーに直接接続するかの2つの選択肢がある。

AC充電とDC充電の選択は、利用可能な充電時間や充電技術のコストなどの要因によって決まる。

AC充電はしばしば低速充電と呼ばれ、費用対効果の高いハードウェアを使用する。対照的に、DC充電は、車載OBCの電力がもはや限界ではなく、より高価な装置(車載DC急速充電器)が必要となるため、急速充電が可能となる。

DC急速充電は、外出先での充電に不可欠であり、20~80%の充電状態(SOC)で約30分の充電時間の需要を満たす。航続距離への不安を取り除き、公共の場での充電ポイントの普及を促進する上で重要な役割を果たしている。

一方、住宅地ではAC充電が充電器の大半を占め、充電の選択肢を大幅に増やしている。

EV充電ソリューション ACおよびDC充電器

AC充電ステーション アプリケーション

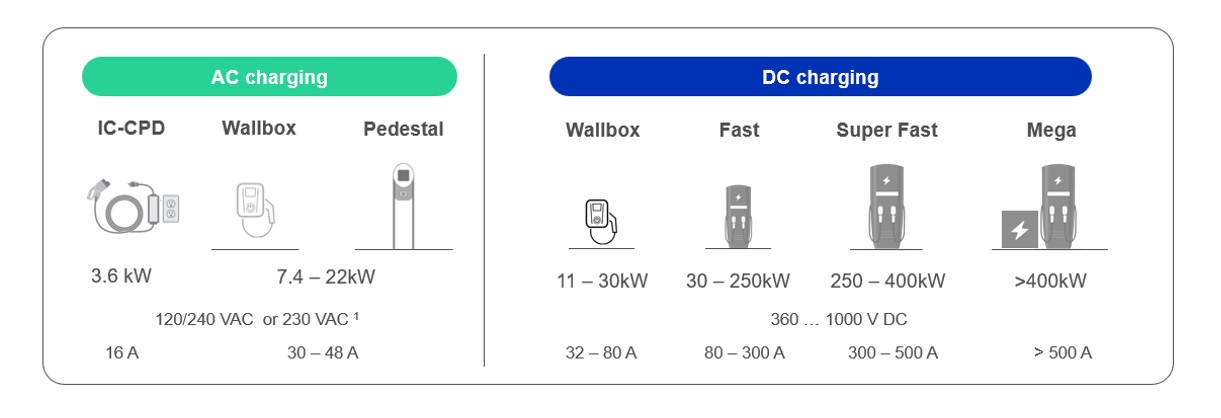

AC充電器(交流充電器)は、電気自動車(EV)の充電に使用され、家庭やオフィスから供給される交流電力を車のバッテリー用の直流電力に変換する。夜間や職場での充電に最適だが、DC充電器よりも時間がかかる。AC充電器の電流センサは出力電流を測定し、漏れを検出して安全性と効率を確保します。

直流充電ステーション アプリケーション

DC充電器(直流充電器)は、送電網からの交流電力をバッテリー用の直流電力に変換することで、電気自動車(EV)を急速充電する。AC充電器よりも高速で、DC急速充電器は20~30分でEVを80%まで充電し、公共ステーションや長時間の移動に最適です。家庭やオフィスでの使用に適したDCウォールボックスは、出力が低く充電時間も長いが、より手頃な価格となっている。

製品ドキュメント

電気自動車の需要が高まるにつれ、高性能の充電インフラの必要性も高まっています。LEMの高度な電流センシング技術がEV供給装置の効率、安全性、信頼性の向上にどのように役立つかをご覧ください。

当社のEV充電ソリューションのパンフレットでは、当社の革新的なソリューションがお客様のEV充電システムをどのように変革し、よりクリーンで持続可能な未来を実現できるかについて詳しく説明しています。

プロジェクトのサポートが必要ですか?

そのアプリケーションに沿ったプロジェクトをお持ちで、LEMにご相談ですか?

下のお問い合わせボタンをクリックしてください。当社の専門家がお客様のニーズに最適なソリューションを見つけるお手伝いをいたします。