Tunnel Magneto Resistance (TMR) Sensor Technology

What is TMR technology?

Tunnel Magneto Resistance (TMR) is a breakthrough in magnetic sensing, offering unmatched sensitivity, perfect thermal performance combined with high precision which is an important set of features for indirect electrical current measurements.

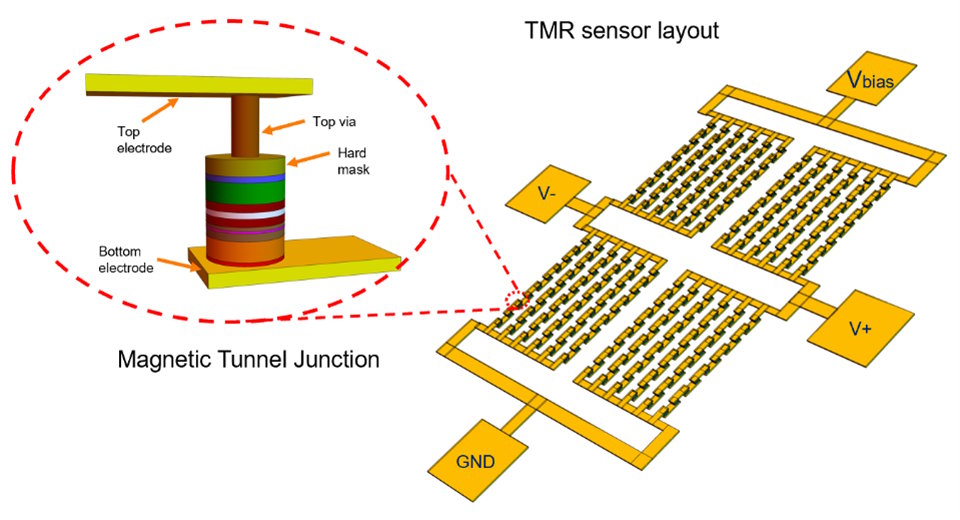

A TMR sensor combines arrays of thousands magnetic tunnel junctions (MTJs) which are able to detect intensity and direction of magnetic field with exceptional accuracy. This technology represents a significant advancement over traditional Hall effect sensors, which have been in use for over a century.

TMR technology is also known for decades, in fact. TMR reading heads for Hard Disc Drives (HDD) were commercialized twenty years ago igniting a new era of high-density data storage. In those times TMR technology had also proposed first viable solutions for Magnetic Random Access Memory (MRAM) entering in competition with traditional silicon memory.

Today, the spectrum of applications extends towards linear and angular magnetic position sensing, a vast variety of threshold magnetic field detectors, ultra-sensitive devices for biomedical and aerospace industry, neuromorphic computing etc. And definitely an important place is also reserved for TMR in our electrified world.

LEM is now integrating TMR sensor technology into its portfolio to meet the growing demand for high-performance current sensing. With its ultra-low offset, high resolution, flexibility in system design and compact footprint, TMR is ideally suited for applications requiring fast protection, high accuracy, wide signal bandwidth and low power consumption.

How TMR Sensors Work

TMR sensor exploits quantum mechanics and its famous tunneling magnetoresistance effect.

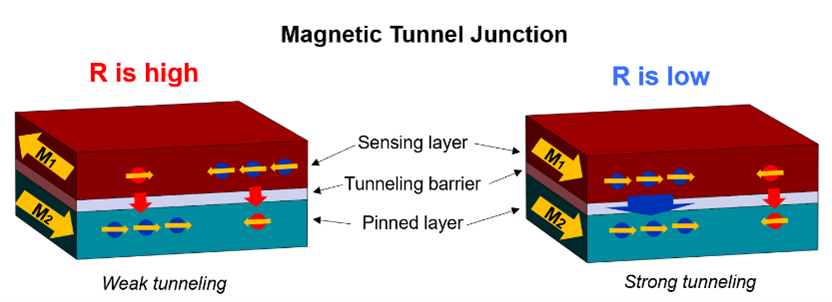

Elemental functional unit of any TMR sensor is an MTJ pillar - a submicron device fabricated from metallic and dielectric layers of nanometer thickness stacked together. Electrical resistance of such an MTJ pillar changes depending on the relative orientation of two neighboring ferromagnetic layers separated by a thin insulating barrier.

The first layer, called a “sensing layer”, follows magnetic field in a linear and non-hysteretic manner. The second layer, named a “pinned layer”, is engineered in a way that its magnetization remains insensitive to magnetic fields. Magnetization direction of the pinned layer defines the sensitivity axis of the sensor.

A magnetic field changes the relative magnetic configuration between sensing and pinned layers, which modifies tunneling probability of electrons through the dielectric barrier thanks to the tunneling magnetoresistance effect. Normally, a low-resistive state is reached when the magnetic field causes pinned and sensing layers to be magnetized in the same direction, while high-resistive state corresponds to their antiparallel configuration. The range of the magnetic field, where the transition between these two states happens, is usually used for magnetic field detection.

It is worth to mention that the ratio of the high- to low-resistive state can easily reach several hundred percent. Such a strong magneto-resistive effect allows TMR sensors to detect small magnetic fields with 10-50 times higher sensitivity compared to traditional Hall effect sensors.

At the same time the TMR effect creates a significantly larger output signal than conventional sensors. Together with more than one order of magnitude lower inherent noise, the TMR sensor offers a considerably higher signal-to-noise ratio requiring a less complex signal conditioning circuitry. This enables an accuracy better than 1% and signal bandwidth larger than 10MHz, which is far beyond the current Hall sensor performance.

Advantages of TMR Over Hall Effect Sensors

TMR technology offers several key advantages over conventional Hall effect sensors, particularly in demanding applications where precision and speed are critical.

| Feature | TMR Sensor | Hall Effect Sensor |

|---|---|---|

| Sensitivity | High | Low to Moderate |

| Resolution | > 12 bits (native) | ≤10 bits (requires oversampling) |

| Output voltage | > 150 mV/V | ~15 mV/V (GaAs) |

| Bandwidth | > 10 MHz | Limited to ~1.5MHz due to required signal conditioning (current spinning) |

| Output Offset | Low | 4x higher depending on signal conditioning |

| Temperature Stability | Excellent | Affected by thermo-mechanical influences |

| Noise Performance | Low 1/f noise | Higher thermal noise |

| Signal Conditioning complexity | Low | High |

| Size & Integration | Compact, flexible layout | Small, monolithic integration possible |

Applications of TMR Sensors in LEM Solutions

LEM’s deployment of TMR sensor technology is focused on next-generation current sensing for high-efficiency power electronics. These applications demand fast protection, high accuracy, and minimal power loss — all areas where TMR excels.

1. SiC and GaN-Based Power Systems

Wide-bandgap semiconductors like Silicon Carbide (SiC) and Gallium Nitride (GaN) enable faster switching and higher efficiency in power conversion. TMR sensors provide the precision and bandwidth needed to monitor current in these systems, ensuring reliable operation and fast fault detection.

2. On-Board Chargers (OBC)

In electric vehicles, on-board charger systems require accurate current sensing to manage charging cycles and protect components. TMR sensors offer high resolution and low offset, making them ideal for integration into compact, high-performance OBC designs.

3. Solar Inverters

Solar energy systems rely on precise current measurement to optimize power conversion and grid interaction. TMR sensors deliver stable performance across temperature ranges and offer the sensitivity needed for low-current detection in residential and commercial solar inverters.

4. Industrial Automation

Automation systems demand fast and accurate current sensing for motor control, robotics, and safety mechanisms. TMR’s high bandwidth and low noise characteristics support real-time monitoring and control in dynamic industrial environments.

5. Fast Protection Circuits

In applications where milliseconds matter, such as fault detection and circuit protection, TMR sensors provide rapid response and high fidelity, enabling immediate action to prevent damage or downtime.

Why TMR is the Future of Magnetic Sensing at LEM

LEM’s adoption of TMR sensor technology marks a strategic move toward more integrated, high-performance sensing and cost-efficient solutions. As the demand for precision, speed, and efficiency continues to grow across industries, TMR already stands out as a robust and scalable solution.

Today, major semiconductor players integrate TMR technology in their process flows. Inevitably, price of a TMR die is to drop further. Meanwhile, academic and industrial R&D labs keep working on new materials for MTJ stacks and advance in more efficient TMR sensor layouts. These trends will further increase performance gap between Hall effect and TMR sensors.

Whether in automotive, renewable energy, or industrial automation, LEM’s TMR sensors are engineered to meet the challenges of tomorrow’s power and control systems.