In many industrial applications, high precision current measurement is a key factor to achieve excellent performances where the measurement technology must achieve its best results. Indeed, there are cases where a limited higher tolerance can cause very significant impacts on the final measured value. Whether for medical equipment or other industrial applications, LEM’s high precision sensors set the standard for current measurement accuracy and are the most precise industrial products on the market today.

The high precision sensors provide levels of stability and precision, about 1–3 parts per million, which makes them the best solution in calibration test benches or in laboratories.

LEM’s High-Performance sensors for High-Precision Applications

Some power-electronics applications require high performance in accuracy, drift and response time. The typical case is the validation of customer equipment that is made through recognized laboratories using high-performance test benches supported by high-technology equipment including extremely accurate current sensors.

These high precision sensors are used for such applications but are more and more required in high-performance industrial applications, medical equipment (MRI, etc.), precision motor controllers, and metering or accessories for measuring and test equipment. LEM has been the leader for years in producing sensors with high performance and competitive costs for these markets.

To achieve this challenging mix of high accuracy and high performance, LEM’s current sensors for the high precision market use an established and proven technology, the Fluxgate technology.

Thanks to this technology LEM high precision transducers achieve accuracies in the parts per million (PPMs) of their nominal value, which is an outstanding results.

The high-accuracy product range include sensors with nominal current from 12.5 A to 24 kA, providing overall accuracies at ambient temperatures (25°C) of only a few PPM. Thermal offset drifts are extremely low, only a few PPM per Kelvin (K).

References from 12.5 to 60 A nominal can be used for PCB mounting, whereas models from 60 A to 24 kA are intended for panel and/or rack-mounting with either onboard or separate electronics. In addition, the Flux-gate technologies provide Galvanic isolation for current measurements of all types of waveforms including AC, DC, mixed signal or complex waveform.

TYPICAL APPLICATIONS FOR HIGH PRECISION

- Test & Measurement

- High voltage Direct Current (HVDC)

- Medical equipment (scanners, MRI, etc.)

- Precision motor controllers

- Metering

- Power Analysers

HIGH-PRECISION EQUIPMENT VALIDATION, TEST & MEASUREMENT

LEM has been the leader for years in producing ultra-precise and cost-competitive current sensors for both traditional and high-performance industrial equipment testing. They provide excellent levels of stability and precision.

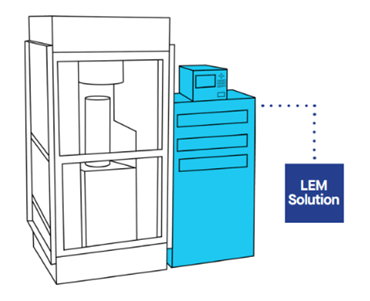

Most power measurement applications are 3-, 4- or even six channel applications. For an easy installation, wiring and use of our sensors, LEM provides complete multi-channel solutions including power supply and sensor connection cables. A power measurement setup consisting of power meter and sensors can be mounted within minutes.

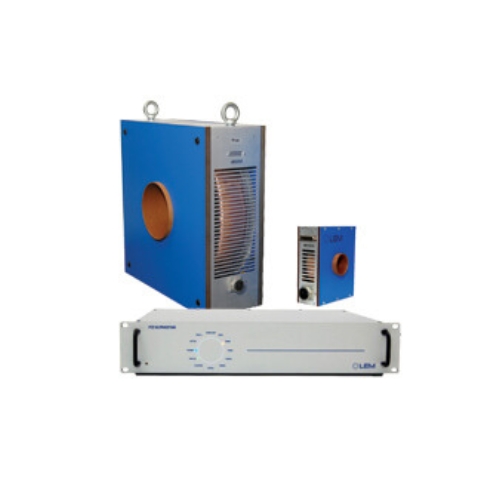

LEM high precision current transducers can be found everywhere where inverters or drives need to be developed or tested. The ITZ product family is normally used for final tests of large low voltage and medium voltage motors and generators. Even if the machine is a pure 50 or 60 Hz drive, LEM high precision sensors are a cost optmized way to measure the current. Alternative current sensor technologies require to switch between different sensors to cover the entire current range which obviously increases the cost of the test system.

The large ITZ sensors for 2 kA and 5 kA are used for development of wind generators and solar inverters.

ITZ Series

- Two parts design - separate head and rack electronics

- Analog output on 15-pin D-sub female output connector

- Status/interlock port on 9-pin D-sub male output connector

- Very fast response time

Additionally, IT transducer family can be used from 60 A to 1000 A for development and test of lower current applications such as small solar inverters, small and medium motors and industrial inverters and power electronics components for automotive applications. Most of the current sensors are used for power and signal analysis but since this technology is so precise some of the sensors are used in calibration labs for DC and AC current calibration.

HIGH VOLTAGE DIRECT CURRENT (HVDC)

High Voltage Direct Current (HVDC) is a technology used to transmit electricity over long distances. HVDC systems are more efficient than the standard AC transmission ones in case the power amount becomes really high, and the power losses can be significantly reduced.

LEM ITL 4000-S sensor can be used for such applications in a Voltage Source Converter (VSC) setup. The VSC technology is a type of HVDC system that converts the voltage from AC to DC or vice versa. The main advantage of VSC technology is that it allows for independent control of active and reactive power, which makes it possible to control the direction of power flow.

HVDC relying on VSC technology is a method of electrical power transmission that uses direct current for sending substantial amounts of electricity over long distances with less energy loss, and it provides better control over the power flow.

ITL Series

- Accuracy Class 0.2S (IEC 61869-2)

- Ingress protection rating IP54.

- Measuring range: 3 x IPN = 12000 A pK

- Overall accuracy: +/- 0.06 % of IPN at +25°C

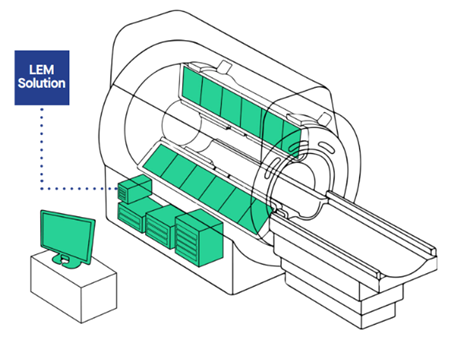

MEDICAL EQUIPMENT ACCURACY – MAGNETIC RESONANCE IMAGING (MRI)

Magnetic resonance imaging (MRI) is a medical imaging technique commonly used to visualize the detailed internal structure of the body. One advantage of an MRI scan is that it is harmless to the patient. It uses strong magnetic fields and non-ionizing radiation in the radio frequency range, unlike CT scans and traditional X-rays which both make use of ionizing radiation.

The MRI high precision sensor measures and ensures the precise level of electric current going to the gradient amplifiers used to generate the magnetic field. The accuracy of the current measurement is a critical factor to be able to generate the optimal magnetic field according to the position of the patient and the body part to be imaged.

The quality of the image provided by MRI scanners is directly linked to current measurement accuracy and, therefore, to the MRI sensor performance. If the sensor is not precise enough this will lead to a blurred and illegible image. LEM high-precision sensors are used for these MRI scanners and other medical equipment requiring faultless power control.

PRECISION MOTION CONTROL FOR PHOTOLITHOGRAPHIC SCANNING STEPPERS

Semiconductor manufacturing heavily relies on intricate photolithographic processes to create nanoscale structures forming integrated circuit on a chip. This process is comparable to traditional photography, involving imaging an illuminated object onto a light-sensitive surface.

In the photolithographic scanning stepper, motion control and positioning are crucial for reproducing nanometer-scale geometries. Positioning involves stepping positioning to a specific position and scanning positioning, controlling wafer and mask movements in opposite directions. The scanning positioning mechanism, with limited travel (10-20mm), uses a linear actuator like a voice coil. Achieving near-perfect synchronization between the two movements is vital, demanding high precision in current measurement.

Ultrahigh precision DC current sensors, such as the LEM ITN family provide the required precision and differential linearity for this application.

The primary alternative, a shunt resistor, faces challenges due to the high drive currents (5-15A), leading to power loss and temperature-induced drift. Additionally, shunt resistors inherently carry a common-mode contribution, absent in a Direct Current Current Transformer (DCCT) where primary and secondary are galvanically isolated.

In conclusion, despite the higher cost of an ultrahigh precision DCCT, its advantages surpass the simpler alternative of a shunt resistor for scanning steppers in semiconductor manufacturing. The technology ensures precise motion control and positioning, essential for achieving nanometer-scale geometries and maintaining the integrity of the semiconductor fabrication process.

HIGH PRECISION CURRENT MEASUREMENT SENSOR FAMILIES

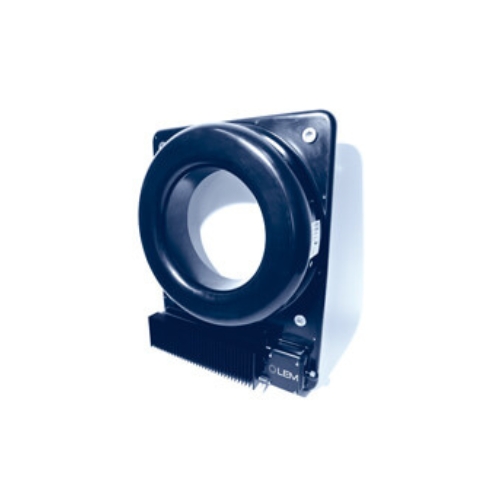

The IT, ITN, and IN product families demonstrate LEM's commitment to innovation and precision of high precision current measurement solutions. These sensors are designed to enable more precise and accurate current measurement, covering to the needs of various high-precision applications.

These product families are not only used in traditional high precision applications but are more and more often applied in industrial and medical applications, specifically medical equipment (scanners, MRI, etc.), precision motor controllers, and metering or accessories for measuring and test equipment.

IT, ITN Series

- Nominal AC&DC isolated current measurements: from 12.5 and 1000 A DC

- Closed loop current transducer using an extremely accurate zero flux detector

- Electrostatic shield between primary and secondary circuit

- Really quick response time

IN Series

- Nominal AC&DC isolated current measurements: from 100 and 2000 A DC

- Closed loop current transducer using an extremely accurate zero flux detector

- Best-in-class accuracy: excellent linearity and minimum electrical offset

- Broad frequency bandwidth (up to 2.5 MHz @±3 dB)

CURRENT SENSORS SOLUTIONS FOR HIGH PRECISION

LEM offers a comprehensive range of current sensor solutions for high precision applications.

Our products are designed to deliver unparalleled accuracy and performance, leveraging advanced technologies such as closed loop Fluxgate.

| Bandwidth | 140kHz - 2500kHz | 500kHz - 800kHz | 50kHz | 100kHz - 500kHz | 2kHz - 300kHz |

| Consumption | 0.07A - 1.87A | 80mA | 0.35A | 60mA - 130mA | 76W - 300W |

| Current Range Max | 300A - 3000A | 60A - 1000A | 12000A | 12.5A - 1000A | 2000A - 24000A |

| Supply Voltage | 15V | 15V | 24V | 15V | 15V |

| Mounting | Panel | Panel | Panel | PCB, Panel | Panel |

| Output | Current | Current | Current | Current | Current |

| Overall Accuracy | 0.0012% - .0075% | 0.02725% | 0.06% | 0.00115% - 0.0509% | 0.0004% - 0.0008% |

| Technology | Closed Loop Fluxgate | Closed Loop Fluxgate | Closed Loop Fluxgate | Closed Loop Fluxgate | Closed Loop Fluxgate |

Certificates and standards

Compliance with the highest industry standards

LEM’s products and processes comply with reference standards in the industry:

- CE marking of Lem transducers in recognition of their electromagnetic compatibility

- IEC standards for high-precision based applications:

- IEC 61010-1 & IEC 61010-2-030 for safety

- IEC 61000-6-2 & IEC 61000-6-3 or IEC 61326-1 for EMC

- RoHS compliant

- ISO TS 16949 certification of all production and development centers (Switzerland and China)

Quality products and services: our priority

Based on our deep knowledge of applications and current measurement technologies, LEM develops both catalog and customized products which can be perfectly tailored to meet your needs in terms of performance, space requirement and cost.

PRODUCT DOCUMENTATION

Explore the cutting-edge technologies LEM offers for high precision applications. Delve into the specifics and download our brochure for a comprehensive understanding:

NEED SUPPORT ON YOUR PROJECT?

You have a project in line with that application and want to discuss it with LEM?

Click on the contact button below and our experts will help you find the best solutions for your needs.