For a welding process to be successful, the 2 parts to be welded must be exposed to an intense heating source usually created with an electrical arc which temperature can reach up to 3000°C. The quality of the welding depends, among others, on a high control of this electrical arc and of the electrical current used to produce it.

LEM current transducers measure this current, contributing to the control and good function of the welding application.

ENHANCE WELDING EFFICIENCY AND SAFETY WITH LEM CURRENT SENSORS

LEM provides current sensors specifically designed for various welding applications. These sensors play a crucial role in ensuring the efficiency, safety, and quality of these applications.

Typical applications for industrial welding include:

- Power supplies for welding

- Power supplies for plasma welding

- Plasma cutting

- Electrolysis

- Inductive heating

In all these applications, LEM's current sensors not only enhance operational efficiency but also contribute significantly to process optimization and quality assurance.

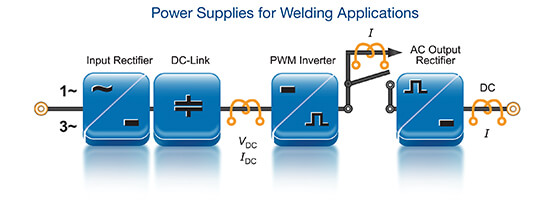

POWER SUPPLIES FOR WELDING

Current sensors are vital components in welding power supplies, enabling precise control of the welding current. They play a crucial role in protecting equipment, enhancing efficiency, supporting quality assurance, and optimizing processes.

To ensure a stable and high-quality weld, precise control of the current is essential. Current sensors provide real-time feedback on the actual current delivered to the welding arc, allowing the power supply to adjust and maintain the desired current level.

Additionally, these sensors help protect the power supply and welding equipment from damage by detecting abnormal conditions such as overcurrent or short circuits. They can trigger protective actions, like shutting down the power supply or activating protective circuits.

By monitoring the current, the power supply can optimize its operation for maximum efficiency, reducing energy consumption and minimizing heat generation—especially important in high-power welding applications.

The data collected by current sensors is invaluable for quality assurance. Analyzing the current profiles of successful welds helps establish benchmarks for future welds. Deviations from these benchmarks can indicate potential issues with the weld.

Furthermore, current sensors contribute to process optimization. In resistance welding, for example, the current profile affects the size and shape of the weld nugget. By monitoring and controlling the current, it is possible to optimize the weld nugget for specific applications.

PLASMA ARC WELDING (PAW): CONTROL AND ACCURACY

Plasma Arc Welding (PAW) is a process that uses a constricted arc or a plasma jet to melt a material, typically metal. It's a type of welding that is known for its precision and control, making it ideal for applications that require high-quality welds.

The plasma arc welding process was introduced to better control the arc welding process in lower current ranges. Plasma enables an advanced level of control and accuracy in order to:

- produce high quality welds in miniature or high precision applications

- increases electrodes’ life for high production requirements

PAW can be used on most metals, including stainless steel, aluminum, and nickel alloys. It can also be used to weld thin materials and in situations where a specific penetration is required.

The plasma arc is more concentrated than other arcs, resulting in a smaller heat-affected zone. This means less distortion of the workpiece and higher quality welds.

Plasma arc welding requires high current levels anywhere between 100 and 600 amperes.

Depending on the type of material used and object welded, a specific current profile must also be maintained to ensure a high-quality weld. This is the role of LEM’s sensors. They measure and control precisely the level of current that is used to heat the plasma, ensuring a strong and lasting weld.

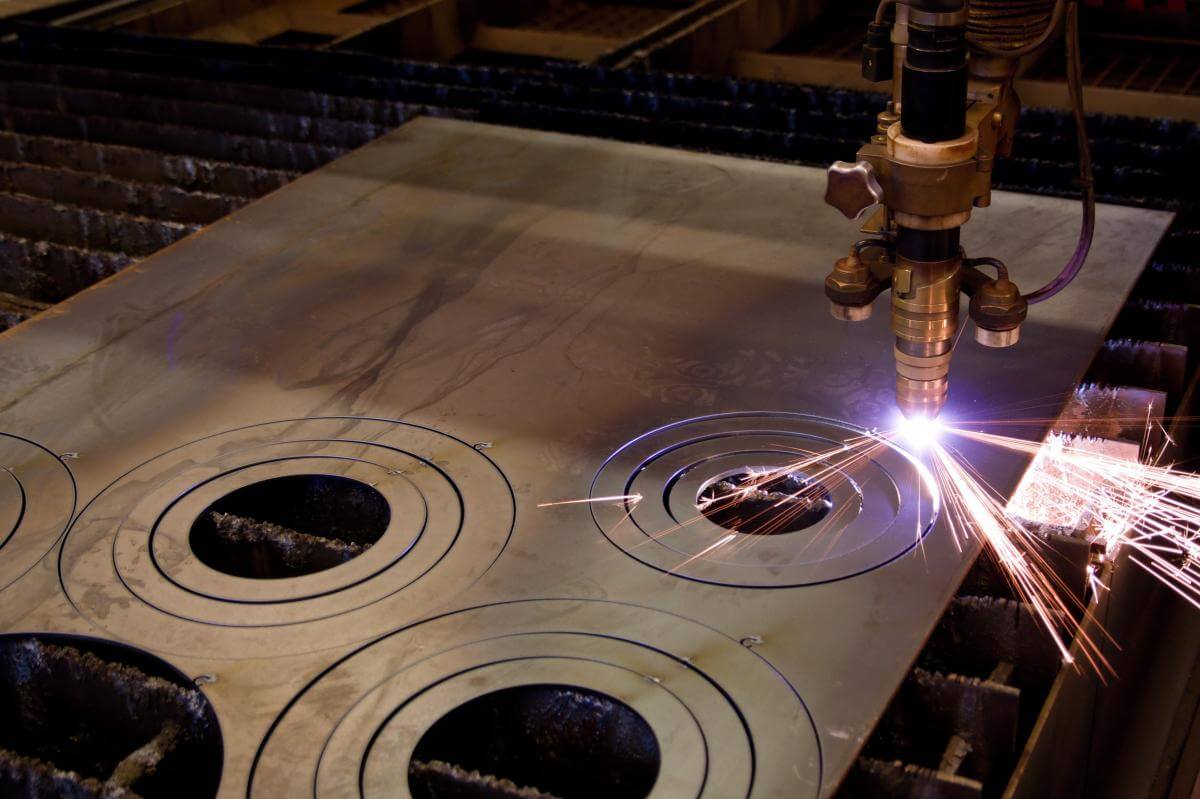

ENSURING CURRENT MEASUREMENT ACCURACY IN PLASMA CUTTING

Plasma cutting uses a “plasma torch”. In this process, an inert gas (in some units, compressed air) is blown at high speed out of a nozzle; at the same time an electrical arc is formed through that gas from the nozzle to the surface being cut, turning some of that gas to plasma. The plasma is hot enough to melt the metal being cut and moves sufficiently fast to blow molten metal away from the incision.

By making a contact by touch to the metal and then move a few millimeters away from the metal, an electrical arc is formed.

In that way the arc is formed and can melt the metal. To maintain the arc continuously, the current through the arc is measured by a current sensor that feeds the value of the current back to a control unit, which regulates it using modern IGBTs (Isolated Gate Bipolar Transistors) to ensure the current intensity of the arc. The accuracy of the measurement is important to guarantee the accuracy and shape of the cut.

For overall welding applications, the HOB series is the perfect fit. HOB sensors benefit from a high frequency range which is particularly interesting for high frequency SIC welding applications.

HOB Series

- High cut-off frequency up to 1 MHz

- Unique short response time of < 200 ns

- Single power supply +5 V

- Creepage / clearance > 11 mm

Current Sensors solutions for Welding

In the demanding field of industrial welding, precise current measurement is crucial for achieving high-quality welds and ensuring operational efficiency. LEM's current sensors are designed to meet these needs, providing accurate and reliable current measurement for various welding applications.

Our sensors help control the welding process, enhance safety, and optimize performance, making them an essential component in modern welding systems.

| LA | LF | |||||

|---|---|---|---|---|---|---|---|

| Current Range Max | ± 150 A | ± 250 A | ± 380 A | ± 450 A | ± 625 A | ± 1050 A | ± 4500 A |

| Bandwidth | 50kHz | 1000kHz | 200kHz | 200kHz | 350 kHz | 200kHz | 200kHz |

| Supply Voltage | 2.5 +/- 0.625 V / 4 V | +3.3V / +5V | +5V | +5V | +3.3V / +5V | +12 V / 15V / +24V | +12 V / +15V |

| Mounting | PCB | PCB | PCB | PCB | PCB | Panel | Panel |

| Overall Accuracy | 1% | 1.2% - 1.45% | 0.83% | 0.68% - 0.83% | 1% - 1.35% | 0.4% - 1.4% | 0.2% - 0.6% |

| Technology | Open Loop Hall Effect | Open Loop Hall Effect | Closed Loop Hall Effect | Open Loop Hall Effect | Closed Loop Hall Effect | Closed Loop Hall Effect |

Certificates and standards

Compliance with the highest industry standards

LEM products and processes comply with reference standards in the industry:

- CE marking of LEM transducers in recognition of their electromagnetic compatibility

- IEC standards for welding applications:

- IEC 61800-5-1 for safety

- IEC 61800-1 & IEC 61800-2 for climatic and mechanical constraints

- IEC 61800-3 for EMC

- RoHS compliant

- ISO TS 16949 certification of all production and development centers (Switzerland and China)

- IRIS certification :

- Geneva Head Office since September 2007 (LEM Switzerland SA)

- Beijing production sites since 2008 (LEM Electronics China Co. Ltd)

- Sofia production site since 2016 (LEM Bulgaria EOOD)

Quality products and services: our priority

Based on our deep knowledge of applications and current measurement technologies, LEM develops both catalog and customized products which can be perfectly tailored to meet your needs in terms of performance, space requirement and cost.

PRODUCT DOCUMENTATION

Ready to explore cutting-edge solutions for precise current sensing in welding and automation?

Our Industry Automation Solution Brochure dives into how LEM’s high-performance sensors optimize efficiency and accuracy in demanding environments.

Whether you're looking to improve weld quality, ensure safety, or enhance productivity, this brochure offers a complete guide to our advanced technologies designed for industrial automation applications.

NEED SUPPORT ON YOUR PROJECT?

You have a project in line with that application and want to discuss it with LEM?

Click on the contact button below and our experts will help you find the best solutions for your needs.