LEM provides a broad range of current sensors for automotive traction inverters that enable a high level of integration through different assembly concepts such as onto the gate driver boards, plug-and-play with the power module, with integrated busbar, and soon without the need for magnetic core. LEM works with all the major car, bus, trucks manufacturers and Tier-1 suppliers in the world.

WHY ARE CURRENT SENSORS SO IMPORTANT IN MOTOR CONTROL APPLICATIONS

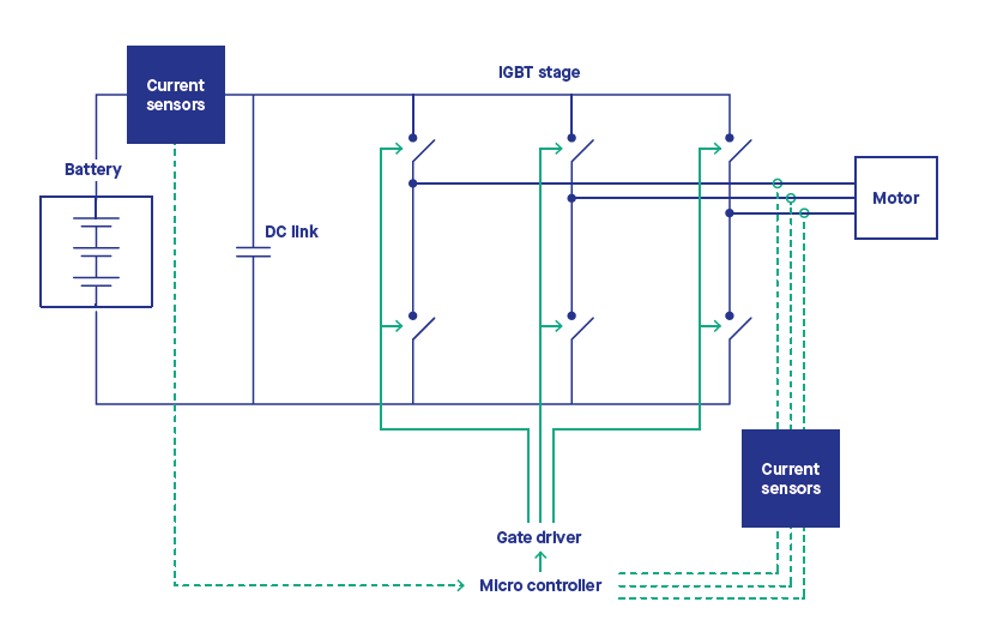

Electric and hybrid vehicles need traction inverters to drive electric motors up to several hundreds of kW with a high degree of precision and reliability.

Current sensors are crucial for automotive motor control applications for several reasons:

Torque Control

Accurate torque control is critical in passenger cars as it enhances vehicle safety by reducing the risk of wheel slippage or loss of control especially in slippery or challenging road conditions, it ensures highest level of efficiency for the traction system under large range of operating conditions, it offers the best driving experience through smooth and optimum acceleration and regenerative breaking.

The torque produced by an electric motor is directly proportional to the current flowing through its windings. By monitoring accurately this current, a control loop taking into account different parameters can regulate the torque output of the motor.

Fault and overload Detection

An abnormal increase or decrease in current levels can indicate faults such as short circuits, open circuits, or winding failures within the motor. By continuously monitoring the current, the control system can detect these faults early, allowing for timely shutdown to prevent further damage. The goal is to guarantee what we call the “functional safety” of the system.

Key characteristics of an automotive current sensor for motor control

Current sensors for traction inverters need to reach best tradeoff between various characteristics.

Wide current measuring range: A current sensor for automotive traction inverter should be able to sense current over a large range, from 0A up to thousand amps to cover all possible operation point of the motor.

High accuracy and immunity against external fields: measuring accurately the current allows to estimate accurately the torque of the motor. Note that some errors, such as the offset, can be compensated at the system level during operation while external fields can introduce additional source of errors. For this reason, a good understanding of the current sensor technology and how the product is designed into the inverter is key to get the best performance.

High bandwidth: as the primary purpose of the current sensor is to monitor the current flowing into the motor, it is key that the current sensor has a bandwidth high enough, typically above 40kHz, to follow the fundamental frequency of the motor that can reach up to 2kHz. Higher bandwidth allows to measure the pwm frequency of the inverter and offer a wide range of information, providing higher level of flexibility to control the motor.

Fast response time: current sensors with fast response time allow to protect quickly the motor from short circuits for example in the motor winding.

High level of integration and easy assembly: despite high power capabilities, it is key for the inverter to remain compact as it facilitates its assembly into the vehicle and allows to offer more space to the passengers. Compact current sensors with various form factors and assembly concept on the gate driver board, on the power module or on the busbar offer design flexibility.

Quality and reliability: as any automotive components, it is key that the current sensor is designed to operate reliably in rugged conditions over the expected lifetime of a passenger car. And, last but not least, the quality at the component level but also over the manufacturing and complete supply chain needs to meet the most stringent automotive quality standards.

MAIN TECHNOLOGIES FOR TRACTION INVERTER CURRENT SENSORS

Many technologies exist to sense current. But the popular ones are the ones that offer the best tradeoff between cost, size, performance and easiness of use:

- Core based Hall effect open loop current: simple to use, good accuracy with high signal to noise ratio, high bandwidth, high immunity against external field. Although they tend to be bulky, various form factors enable overcoming this limitation.

- Coreless Hall effect open loop current sensor: offers a high level of integration at the lowest cost. This require extensive design effort and stable manufacturing process to guarantee lifetime performance in every conditions.

- Shunt: particularly cost effective for low power applications where current can flow onto a PCBA, and immune against external field. It however dissipates significant power loss when current increase. Additional circuitry is needed to ensure isolation.

LEM current sensors for automotive traction inverters

LEM offers a wide range of current sensors with different form factors specifically designed for traction inverters, allowing to sense current on the motor phases, on the DC link of the battery and even on the rotor winding in case an externally field excited motor replaces the permanent magnet.

Motor control architecture

All current sensors available are core-based Hall effect current sensors, with a large offering of form factors to enable high level of integration and an easy assembly into the inverter.

Phase Motor Current Sensing Solutions

Phase measurement in motor control applications is essential for monitoring and adjusting the timing and synchronization of the motor's phases, ensuring efficient operation and accurate control of speed and torque.

For phase measurement, we recommend the HAH3 Series, particularly the HAH3 S07/SP42 mounted on power modules.

HAH3 Series

- Three phase open loop automotive Hall current sensor

- Available with 800A, 900A, 1000A, 1100 and 1200A measuring range

- 3% global accuracy over temperature and lifetime

- 50kHz bandwidth with 2µs fast response time

DC Link Current Sensors for Enhanced Performance

The DC link is crucial in motor control applications for current sensors as it provides a stable voltage reference, enabling accurate current measurement and efficient motor operation.

The HSTDR Series with integrated busbar is ideal for DC Link.

HSTDR Series

- Measuring range up to ±1,500 A.

- < 3.5% global accuracy over temperature and lifetime.

- 40kHz bandwidth with 3μs fast response time.

Current Sensors for Externally Field Excited Rotor

Rotor external excitation consists in sending current to a winded rotor to dynamically magnetize it.

For this application, HMSR sensors integrated into surface-mounted devices (SMD) on printed circuit board assemblies (PCBA) are the preferred products.

HMSR Series

- Current range 6-30 Arms continuous at 125°C (75 A peak)

- Isolation: 4,950 Vrms

- Global accuracy -25°C: 0.78 %

- Global accuracy -Over T° C: 1.4 %

AUTOMOTIVE MOTOR CONTROL PRODUCTS

| |||||||

|---|---|---|---|---|---|---|---|

| Bandwidth | 50kHz | 50kHz | 50kHz | 50kHz | 50kHz | 50kHz | 50kHz |

| Consumption | 15mA | 15mA | 15mA | 15mA / phase | 15mA / phase | 15mA / phase | 15mA / phase |

| Current Range Max | 1 Phase +/- 900A | 1 Phase +/- 1200A | 1 Phase +/- 1500A | 2 Phases +/- 650A | 3 Phases +/- 900A | 3 Phases +/- 900A | 3 Phases +/- 1200A |

| Supply Voltage | +5V | +5V | +5V | +5V | +5V | +5V | +5V |

| Mounting | Busbar | Integrated Busbar | Busbar | Busbar | Busbar | Busbar | Infineon Hybrid Pack |

| Output | Through-Hole PCB Voltage | Voltage Molex Connector | Voltage Tyco Connector | Voltage JAM Connector | Voltage Hirose Connector | Voltage Molex Connector | Voltage Pressfit |

| Overall Accuracy | 2% | 3.2% | 3.75% | 3.2% | 3.5% | 4.25% | 3.2% |

| Technology | Open Loop Hall Effect | Open Loop Hall Effect | Open Loop Hall Effect | Open Loop Hall Effect | Open Loop Hall Effect | Open Loop Hall Effect | Open Loop Hall Effect |

Quality

LEM products meet all quality requirements for the automotive industry and comply with RoHS specifications. All our production and development centers are certified with ISO TS 16949 (in Switzerland and in China).

Based on our deep knowledge of applications and current measurement technologies, LEM develops both catalog and customized products which can be perfectly tailored to meet your needs in terms of performance, space requirement and cost.

PRODUCT DOCUMENTATION

Discover LEM’s leading technologies for automotive applications. Our automotive expertise does not only cover Battery Management Systems. LEM also provides innovative solutions for motor control and electric vehicles supply equipment (EVSE). Dive into the details and download our brochure for an insightful exploration:

NEED SUPPORT ON YOUR PROJECT?

You have a project in line with that application and want to discuss it with LEM?

Click on the contact button below and our experts will help you find the best solutions for your needs.