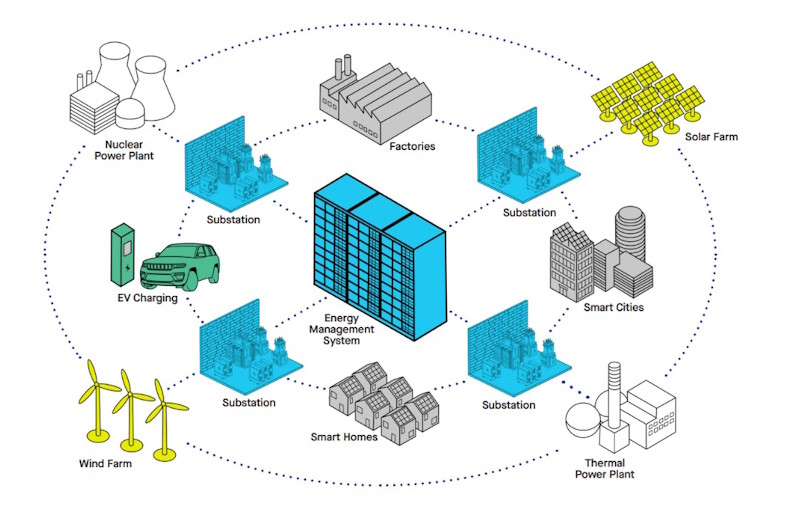

The intelligent electricity distribution network (Smart Grid) is the backbone of the energy system.

Our energy system is passing through a radical transition. The most impacting changes are the introduction of the electrical vehicles, and the spread of distributed generation, made by renewable energies.

Smarter equipment is needed for the Smart Grid to provide reliable integration of renewable energies and distributed energy resources.

LEM allows to improve the Grid capabilities, offering a wide range of sensors and devices which allow to monitor remotely and in real time the technical features of the energy distribution system.

What is a Smart Grid?

The intelligent electricity network, also known as the smart grid, serves as the foundation for every smart city by accomplishing the following key functions:

- Informing "Prosumers": The smart grid provides valuable information to "prosumers," individuals or entities that both consume and produce energy. This information empowers them to take decisions about how, when, and whether to use, store, or even sell electricity. This is particularly relevant for those with solar panels on their rooftops. The aim is to encourage the active participation of residential, commercial, and industrial buildings in energy conservation and efficiency.

- Facilitating Integration of Distributed Renewable Energies: The smart grid ensures the reliable integration of distributed renewable energy sources, energy storage systems, and electric vehicle charging stations.

- Enhancing Grid Components: The smart grid incorporates intelligent solutions such as sensors, intelligent electronic devices, and smart meters. These components enable control, automation, remote monitoring, and real-time data sharing. This collective intelligent solutions contribute to improve the grid management and responsiveness

Common applications for smart grid solutions are:

- Distribution Automation – Fault Detection, Isolation & Restoration

- Grid Monitoring (e.g. Intelligent substations)

- Protection & Safety

- Distribution Transformer Monitoring

- Distribution Automation – Voltage Control

- Power Quality

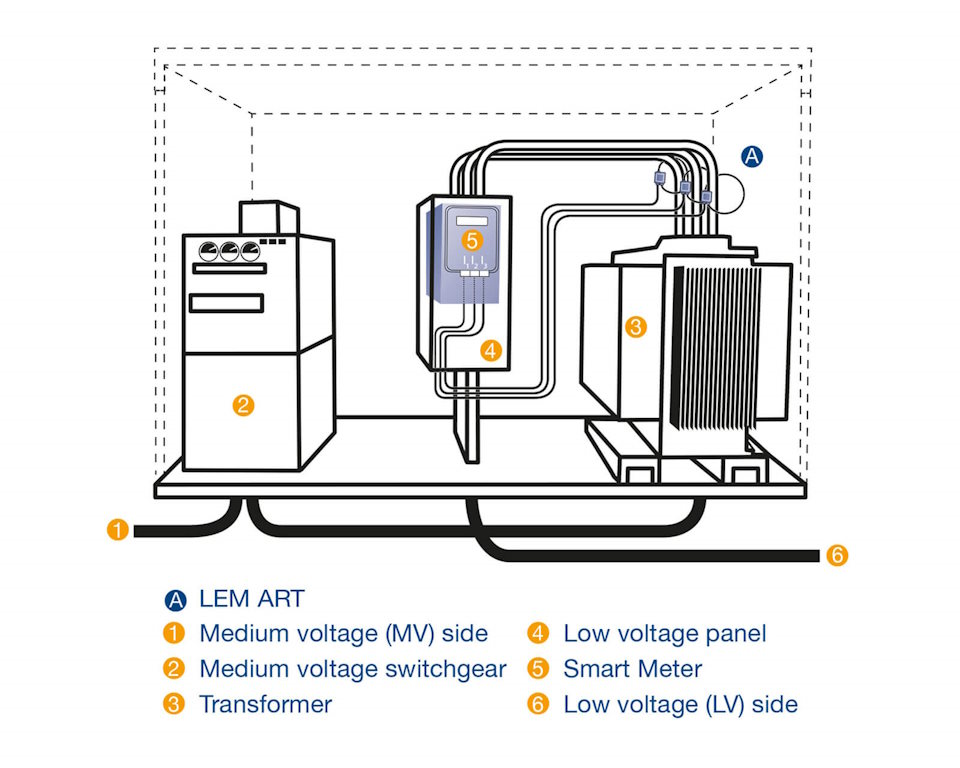

Smart Grid Technology in Medium Voltage Low Voltage Substations

This smart grid application example involves the utilization of flexible LEM ART Rogowski coil sensors in conjunction with a smart meter connected to the low-voltage (LV) side of a distribution transformer within an MV/LV substation.

The software embedded in the smart meter performs calculations based on the LV measurements, enabling the determination of many indicators useful to identify the status of the electrical system. This information includes oil temperature, ageing rate, current values, and the power flow.

This innovative approach offers a more cost-effective distribution grid management without the need for additional sensors on the MV side. The smart meter, when coupled with the ART coils, achieves an overall accuracy better than 1%, increasing the accuracy achieved with conventional current transformers (CTs).

In the MV/LV substation, the power flow is transformed from medium to low voltage. Inside the low voltage board, the smart meter allows to monitor constantly the power quality and to plan the predictive maintenance. The three Rogowski sensors ART transmit the informations from the cables to the energy meter.

Advantages of distribution system operators include:

- Real-time monitoring of the electrical parameters.

- Creation of LV load curves for consumers, producers, and transformers, enabling the detection of unexpected losses and to increase efficiency.

- Aggregation of active energy distributed by each MV-LV transformer, facilitating the detection of non-technical issues on the MV side of the smart grid.

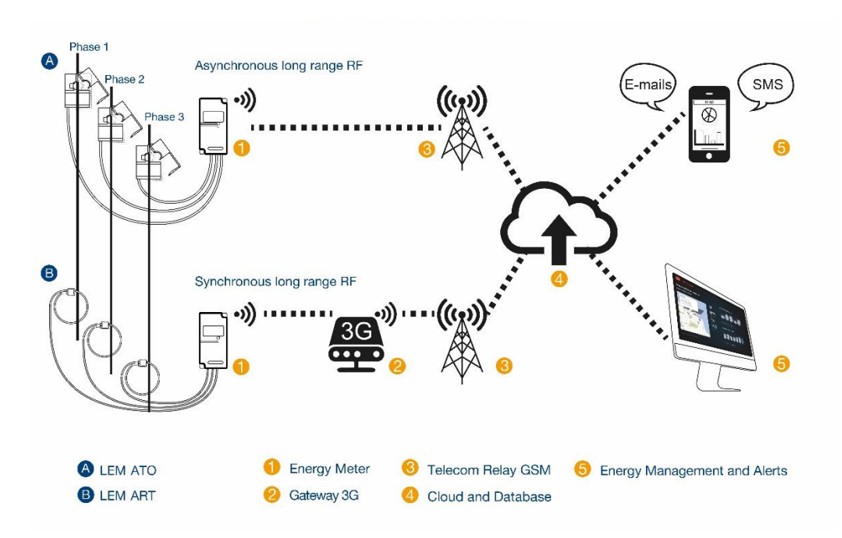

IoT Remote Energy Monitoring for the Smart Grid

The Internet-of-Things (IoT) is exceptionally well-suited for the implementation of smart grids, primarily due to the extensive range requirements and the minimal data size required for transmission. Leveraging narrow-band RF, which is the standard for long-range communication, enables the development of an innovative remote energy monitoring solution. This solution involves deploying wireless energy meters for the remote monitoring of electrical equipment, incorporating hardware, M2M connectivity (such as LORA, SIGFOX, 3G/GPRS), and utilizing web services to manage the collected data, including history, alerts, graphs, statistics, etc.

This IoT solution streamlines network implementation and user installation, reduces infrastructure costs, and is typically compatible with existing solutions. The approach is particularly well-suited for IoT applications due to its small power payload, long-range requirements, and the minimal data size necessary for transmission. The IoT star network configuration is commonly used in the deployment of smart grids.

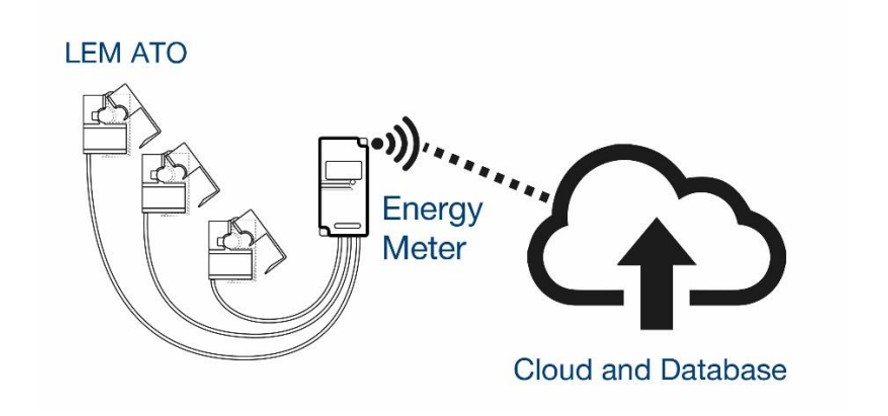

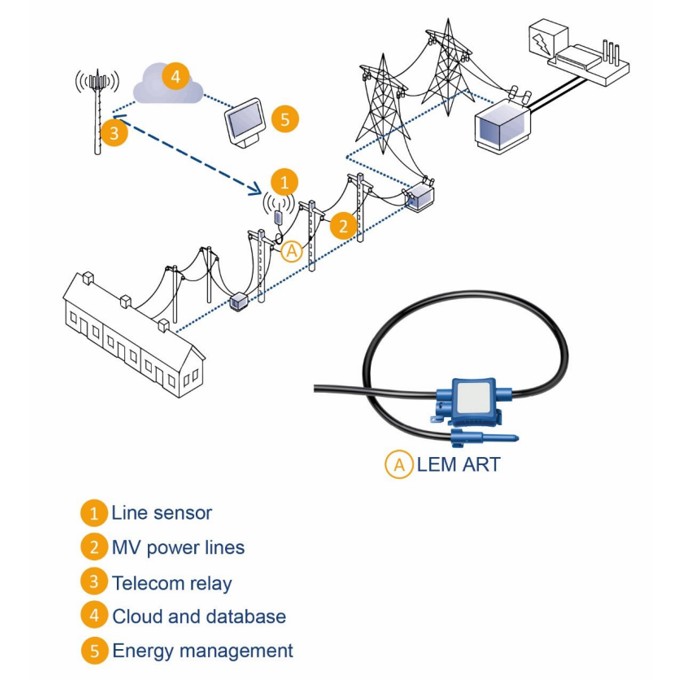

The typical application for energy monitoring aims to identify energy consumption balance and analyze overconsumption to pinpoint areas that require attention. Each wireless energy meter (1), utilizing ATO (A) or ART (B), connects to the RF long-range internet (2) and transmits (3) maintenance data to a secure web server (4).

End-users can remotely monitor equipment usage, including cycles, working time, consumption, etc., and receive alerts when anomalies such as power loss or power peaks are detected (5). Devices with electrical motors, ventilators, pumps, and compressors are among the typical equipment with monitored energy consumption.

The advantages of this solution include the simplicity of installing ATO or ART, internet connectivity, real-time measurements, and the autonomy of the energy meter. The operating mode involves RMS current acquisition every 1s for 10s and sending current consumption statistics every 10 or 15 minutes.

Key advantages of IoT-based Remote Energy Monitoring:

- No need for deploying a local network infrastructure

- Monitoring of both outdoor and indoor equipment

- Wide area coverage

- Very low energy consumption, resulting in long-lasting autonomous energy meters

- Affordability and deployability with LEM ATO or ART sensors

Smart Grid Solutions on Distribution Overhead Line Monitoring

New line current sensors enable utilities to monitor overhead distribution lines, maximizing their capacity and preventing clearance violations to enhance the reliability and efficiency of the MV Distribution Grid.

The monitoring of overhead power lines has become faster, easier, and more cost-effective with the advent of new Internet of Things (IoT) telecom networks such as NB-IoT and LPWAN. Utilizing a line sensor (1) installed between two MV poles (2), grid operators can visualize real-time current flow, optimizing power line capacity for improved electricity distribution. The wireless line sensor (1) transmits data through a telecom relay (3) to a secure cloud-based database (4) or an on-premises system. The energy management platform (5) can regulate, alert, and notify maintenance teams as needed. The latest line sensors leverage the LEM Rogowski coil ART (A) for current measurement, aging detection based on current levels, and prioritization of line capacity.

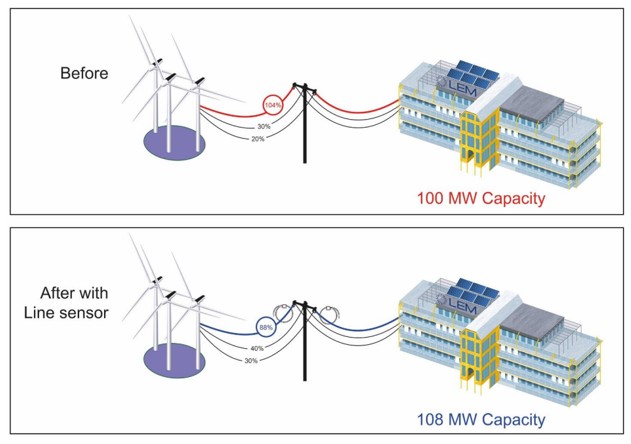

Previously, without visibility into the grid, the distributed renewable energy through an overhead line could lead to overloading (depicted in red). However, with the implementation of a three-phase line sensor system, excess power in one line can be redistributed to parallel or close lines (shown in black), bringing the initial line’s capacity to an acceptable level (depicted in blue). This optimized redistribution results as an optimization of the overall capacity output of the power grid (refer to figure 1).

Figure 1: Before and after line sensor installation

Moreover, the line sensor (designed for 1-35kV distribution grids) offers periodic time-synchronized measurements, enhancing situational awareness and operational efficiency. It provides information on electrical parameters, as well as conductor surface temperature. The sensor also detects fault conditions, enabling their identification and notification. In a meshed network, this three-phase line sensor system ensures real-time equalization among different lines. For AC measurement, the LEM ART split-core Rogowski coil offers several advantages, as summarized in the table below, compared to two other current measurement techniques normally used.

SMART GRID PRODUCTS

LEM provides innovative, accurate, reliable, easy-to install, non-intrusive smart grid sensors for better performance of the grid and smarter cities.

| ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bandwidth | 20Hz - 6000Hz | 1500Hz | 1500Hz | 10Hz - 400Hz | 30Hz - 2000Hz | 300kHz - 420kHz | 320kHz | 462kHz | 50Hz - 60Hz | 50Hz - 60Hz | - | 20Hz - 6000Hz |

| Consumption | 30mA - 35mA | 350mA | 100mA | - | 30mA | - | - | - | - | - | 100mA | 30mA |

| Current Range Max | 2000A - 3000A | 5000A | 5000A | 5A - 2375A | 10A - 400A | - | - | - | 5A - 150A | 6A - 176.7A | 20A - 400A | 600A - 1800A |

| Supply Voltage | 20V - 50V | 16V - 31V | 10V - 32V | 24V | 12V - 24V | Self Powered | Self Powered | Self Powered | Self Powered | 20V - 28V; Self Powered | 20V - 50V | 20V - 50V |

| Installation | On Primary Fastening | DIN Rail | DIN Rail | Panel / DIN Rail | Panel / DIN Rail | On Primary Fastening | On Primary Fastening | On Primary Fastening | On Primary Fastening | DIN Rail / On Primary Fastening | Panel / DIN Rail | Panel |

| Output | Current | Current | Current | Current | Current | Voltage | Voltage | Voltage | Current | Current | Current | Voltage |

| Overall Accuracy | 1% | 0.5% | 0.5% | 1% | 1% | 0.5% | 0.5% | 0.5% | 1.5% | 1% - 1.5% | 1% - 2% | 1% |

| Technology | Open Loop Hall Effect | Integrator | Integrator | Current Transformer | Prime Air- Core | Rogowski Coil | Rogowski Coil | Rogowski Coil | Current Transformer | Current Transformer | Open Loop Hall Effect | Open Loop Hall Effect |

What is a Rogowski coil?

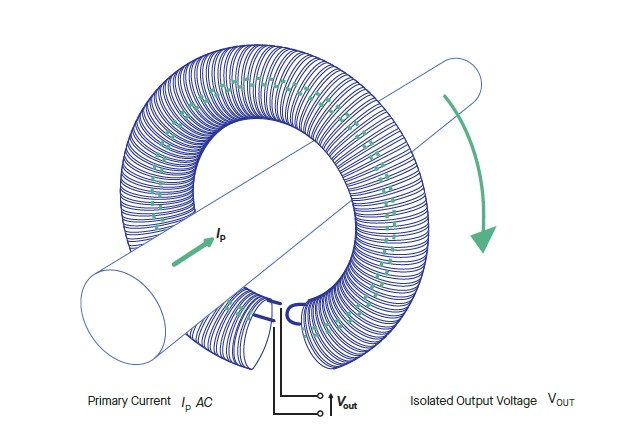

A Rogowski Coil is used to create a flexible sensor that easily wraps around the conductor to be measured. It is made by a helical coil of wire with the lead from one end returning through the center of the coil to the other end, ensuring that both terminals are located at the same end of the coil. The length of the coil is chosen based on the relevant primary cable diameter to provide optimal transfer characteristics.

This technology offers precise detection of the rate of change (derivative) of the primary current, inducing a proportionate voltage at the terminals of the coil.

Certificates and standards

Compliance with the highest industry standards

LEM products and processes comply with reference standards in the industry:

- CE marking of LEM transducers in recognition of their electromagnetic compatibility

- IEC standards for automation applications:

- IEC 61869-2,-6,-8, -10, -14, -15 for performances

- IEC 61010-1, -2-030, -2-032, -031 for safety

- IEC 61800-1 & -2 for climatic and mechanical constraints

- IEC 61000-6-2 & -6-3 or IEC 61326-1 for EMC

- RoHS compliant

- ISO TS 16949 certification of all production and development centers (Switzerland and China)

Quality products and services: our priority

Based on our deep knowledge of applications and current measurement technologies, LEM develops both catalog and customized products which can be perfectly tailored to meet your needs in terms of performance, space requirement and cost

Product Documentation

Explore our comprehensive Smart Grid brochure for detailed insights and solutions to optimize your energy management systems.

Gain knowledge about the latest advancements in Smart Grid technology and practical methods to enhance your projects.

NEED SUPPORT ON YOUR PROJECT?

You have a project in line with that application and want to discuss it with LEM?

Click on the contact button below and our experts will help you find the best solutions for your needs.