Power supplies are fundamental to any electronic device. Power electronics applications such as EV chargers, computers, welding and automation or medical devices all require efficient current control, monitoring, regulation and protection.

The emergence of Artificial Intelligence and Internet of Things are driving strong demand of data centers, where power distribution and power supplies play a critical role. Furthermore, the adoption of wide bandgap semiconductors Silicon Carbide (SiC) and Gallium Nitride (GaN) has improved performance, reduced size and increased efficiencies of power supplies.

Current sensors ensure:

- Stable power supply

- Accurate currents conversions depending on the various stages

- Timely information in case of corrections or potential switching

- Quick reactions in the event of emergency and failure.

Current Measurement for Power Supplies

In many applications, the voltage from the grid has to be converted to DC voltage or adjusted to a different AC waveform. The main purpose of a power supply is to convert electric current from a source to the correct voltage, current, and frequency to power the load. A current transducer measures the output current to ensure a stable power supply.

Typical applications for Power Supplies

- UPS: Uninterruptible Power Supplies

- SMPS: Switched Mode Power Supplies

- Linear regulators

- Bipolar power supplies

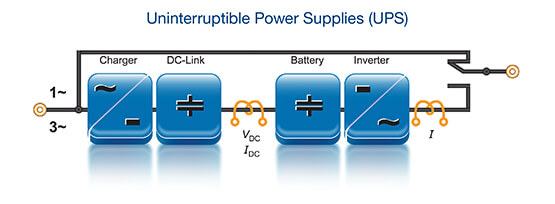

Uninterruptible Power Supplies Application (UPS)

Uninterruptible Power Supplies (UPS) are crucial for providing continuous and clean power to critical loads during power failures. Unlike emergency generators, UPS systems deliver immediate power, though typically for a short duration, allowing sufficient time for backup power - normally a battery - to activate or for equipment to shut down safely.

UPS systems are used in applications with critical loads, such as hospitals, industry or telecommunication and IT infrastructure. The main driver for growth in the UPS market is the proliferation of data centers, triggered by the rapid adoption of Artificial Intelligence. UPS systems not only ensure power continuity but also filter out voltage spikes, drops, and noise, maintaining a stable power quality.

Current sensors play an essential role in UPS systems by monitoring load currents, enabling efficient regulation, and preventing overloads.

They safeguard critical systems by detecting anomalies and ensuring a seamless transition to battery power during outages, thereby preserving data integrity.

These current transducers are integral to maintaining the reliability and efficiency of Uninterruptible Power Supplies, as they provide precise measurements that help optimize energy usage and enhance overall system performance.

By ensuring accurate current monitoring, current sensors contribute significantly to the safety and stability of UPS operations, making them indispensable components in modern power supply solutions.

The HLSR current sensors are a component of choice for small Uninterruptible Power Supplies.

HLSR Series

- DC&AC isolated current measurement with 5 ranges: 10 ARMS, 20 ARMS, 32 ARMS, 40 ARMS, 50 ARMS

- Access to voltage reference

- Low offset & gain drift

Switched Mode Power Supplies Current Sensing (SMPS)

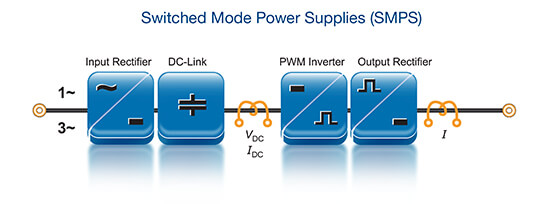

Switched-Mode Power Supplies (SMPS) are highly efficient devices that convert electrical power from one form to another using high-frequency switching.

They are widely used to provide regulated DC voltage for various electronic devices, including laptops, set-top boxes, and smartphone chargers.

Unlike linear power supplies, which are bulky and inefficient, SMPS are compact, lightweight, and typically achieve efficiencies above 85%. The efficiency of Switched-Mode Power Supplies comes from their use of switches and non-dissipative passive elements like inductors and capacitors, which minimize energy loss.

In Switched-Mode Power Supplies, current sensors provide accurate in-circuit current measurements, which are essential for limiting over-current, optimizing circuit performance, and controlling power circuits.

By converting the sensed current to a measurable low voltage, current sensors enable precise control and regulation within the SMPS, contributing significantly to the overall efficiency and reliability of the power supply.

Current Sensors solutions for Power Supplies

Power supplies demand efficient current control, monitoring, regulation, and protection to ensure their integrity and proper functioning. LEM current sensors are designed to meet these needs.

Below is a table showcasing our applicable products and their technical specifications, highlighting how LEM current sensors can optimize performance and reliability in power supply and UPS applications.

| LF | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Current Range Max | ± 180 A | ± 250 A | ± 75A | ± 450 A | ± 625 A | ± 250 A | ± 4500 A | ± 2000 A | ± 1100 A |

| Bandwidth | 200kHz | 100 kHz | 300 kHz | 200kHz | 350 kHz | 1000kHz | 200kHz | 180kHz | 240kHz |

| Supply Voltage | +5V | +5V / +3.3V | +5V / +3.3V | +5V | +5V / +3.3V | +5V / +3.3V | +12 V / +15V / +24V | +5V / +3.3V | +5V |

| Mounting | PCB | PCB | PCB | PCB | PCB | PCB | Panel | On primary fastening | Panel |

| Overall Accuracy | 0.8% - 1% | 1% | 1.25% - 1.5% | 0.68% - 0.83% | 1% - 1.35% | 1.2% - 1.45% | 0.2% - 0.6% | 1% - 1.25% | 1% |

| Technology | Closed Loop Hall Effect | Closed Loop Hall Effect | Open Loop Hall Effect | Open Loop Hall Effect | Closed Loop Hall Effect | Open Loop Hall Effect | Open Loop Hall Effect |

Certificates and standards

Compliance with the highest industry standards

LEM products and processes comply with reference standards in the industry:

- CE marking of LEM transducers in recognition of their electromagnetic compatibility

- IEC standards for power supply-based application :

- IEC 62040-1 & IEC 60950-1 for safety

- IEC 61800-1 & IEC 61800-2 for climatic and mechanical constraints

- IEC 62040-2 for EMC

- RoHS compliant

- ISO TS 16949 certification of all production and development centers (Switzerland and China)

Quality products and services: our priority

Based on our deep knowledge of applications and current measurement technologies, LEM develops both catalog and customized products which can be perfectly tailored to meet your needs in terms of performance, space requirement and cost

NEED SUPPORT ON YOUR PROJECT?

You have a project in line with that application and want to discuss it with LEM?

Click on the contact button below and our experts will help you find the best solutions for your needs.