Current Sensor ICs: Effective Strategies to Reduce Power Dissipation

Introduction to Current Sensor ICs and Power Dissipation

In the relentless push toward higher efficiency, greater compactness, and thermal optimization, every power loss matters. Especially in high-density power environments like EV powertrains, solar inverters, or industrial drives, even seemingly minor sources of power loss, like a current sensor, can become critical design constraints.

LEM’s Integrated Current Sensors (ICS) are engineered not just for accuracy and compact size, but for ultra-low power dissipation. These sensors help designers manage heat, boost system efficiency, and enable more compact, reliable, and high-performing applications.

Understanding the Causes of Power Dissipation in Current Sensor ICs

Current sensing components can introduce inefficiencies in multiple ways:

- Bias or excitation currents in active components

- Burden voltage, creating measurable voltage drops across the sensor

- Self-heating, affecting thermal equilibrium

- Magnetic losses, particularly in core-based designs

One of the most overlooked contributors is internal resistance (Rint), a factor that can significantly influence total power loss.

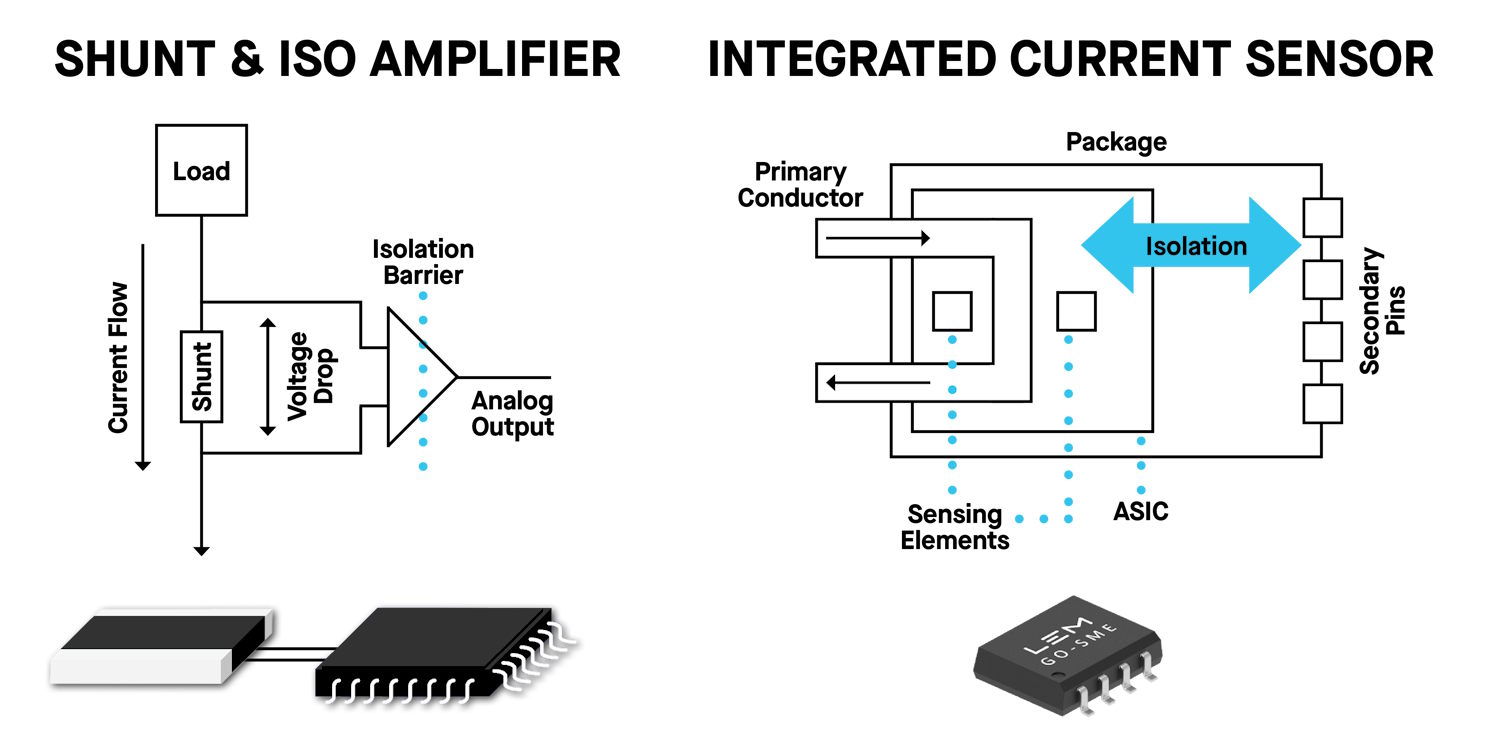

Integrated Current Sensors vs Shunt + Isolator: The Hidden Costs of Resistance

A typical current sensing setup, using a shunt resistor and isolation amplifier, comes with built-in losses:

- A shunt resistor (typically 0.2 mΩ to 1 mΩ)

- An isolation amplifier to ensure safety

- Passive filtering and bias circuitry

For example, just from the shunt at 100 A using a 1 mΩ shunt, P = I²R = 10 W. Add amplifier losses (50 to 100 mW), and you’re rapidly stacking up thermal challenges.

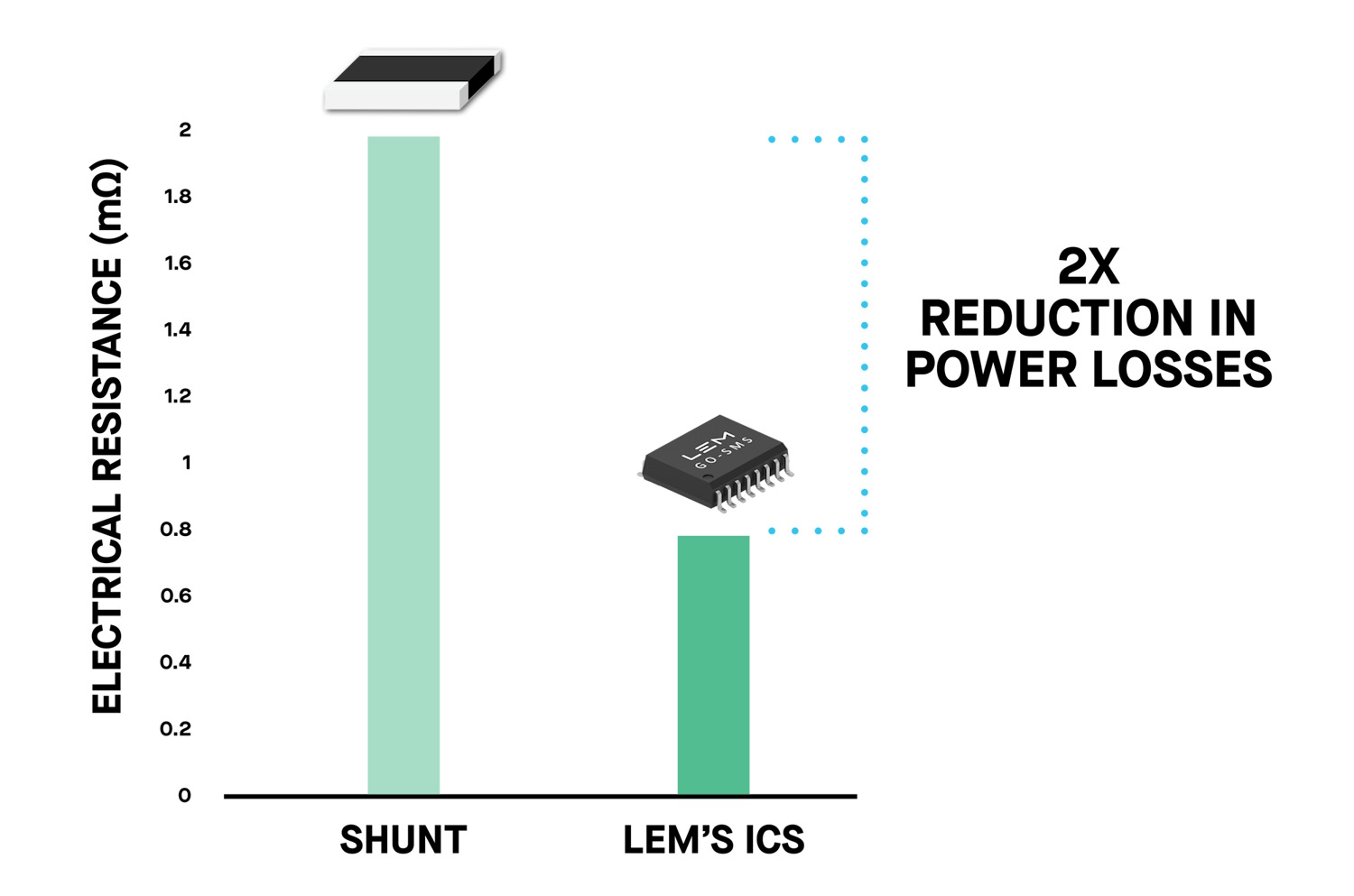

Compare that to a current sensor IC like LEM’s GO-SME Series:

- Internal Resistance: 100 µΩ to 400 µΩ

- Power loss at 100 A: 1 W to 4 W, typically 2 to 5 times lower than a shunt

- Built-in galvanic isolation, no external isolator needed

100 A Current Example | ||

Solution | Resistance | Power Dissipation |

Shunt + ISOamp | 1 mΩ | 10 W |

ICS (GO Series) | 200 µΩ | 2 W |

In multi-channel designs, high-current environments, or thermally sensitive layouts, this difference becomes critical.

What are the real benefits of lower dissipation?

Thermal Relief: Lower sensor heat means fewer design constraints on PCBs, enclosures, and airflow systems.

System Efficiency Gains: Especially important in battery-powered devices, where every watt saved extends runtime and reduces cooling needs.

Increased Power Density: Current Sensor IC devices can be placed closer to heat-sensitive or space-limited areas, enabling tighter, more integrated system layouts.

Applications best suited for Integrated Current Sensors

Integrated current sensors are ideal for any application where high current and low loss must coexist:

- EV onboard chargers & DC/DC converters

- Solar string optimizers & inverters

- High-efficiency industrial drives

- Data center or rack-mounted systems

- Battery energy storage and backup systems

ICS – Efficiency Starts at the Core

Power dissipation at the sensor level may seem small, but in modern high-efficiency systems, it adds up fast. By switching from traditional shunt-based sensing to LEM’s Current Sensor IC solutions, designers can significantly cut heat, reduce component count, and streamline their systems without sacrificing performance or accuracy.