The Importance of surge protection in Current Sensor IC

Enhancing Reliability and Safety in Demanding Applications

Integrated Current Sensors (ICS) are revolutionizing current measurement and insulation by providing a compact, reliable, and precise solution. A critical feature of Current Sensor ICs technology is its ability to withstand electrical surges, ensuring safety and continuity in various demanding applications. As voltage and current surges become more frequent due to evolving standards, Current Sensor IC technology must address these challenges to ensure long-term reliability.

The challenges of surge protection

Electrical surges, characterized by sudden spikes in voltage or current, can be caused by external factors like lightning strikes, switching operations, or internal system fluctuations. These surges can pose serious risks to sensitive electronic equipment, especially in industrial, automotive, and renewable energy sectors where high voltages are common.

Current Sensor IC systems must withstand these high surge voltages to ensure their operational integrity. Surge voltages of up to 10 kV to 20 kV are not uncommon in industrial applications, especially when dealing with impulse voltages from external disturbances. Current measurement systems must therefore be capable of enduring not only the typical operational conditions but also these extreme transient overvoltages.

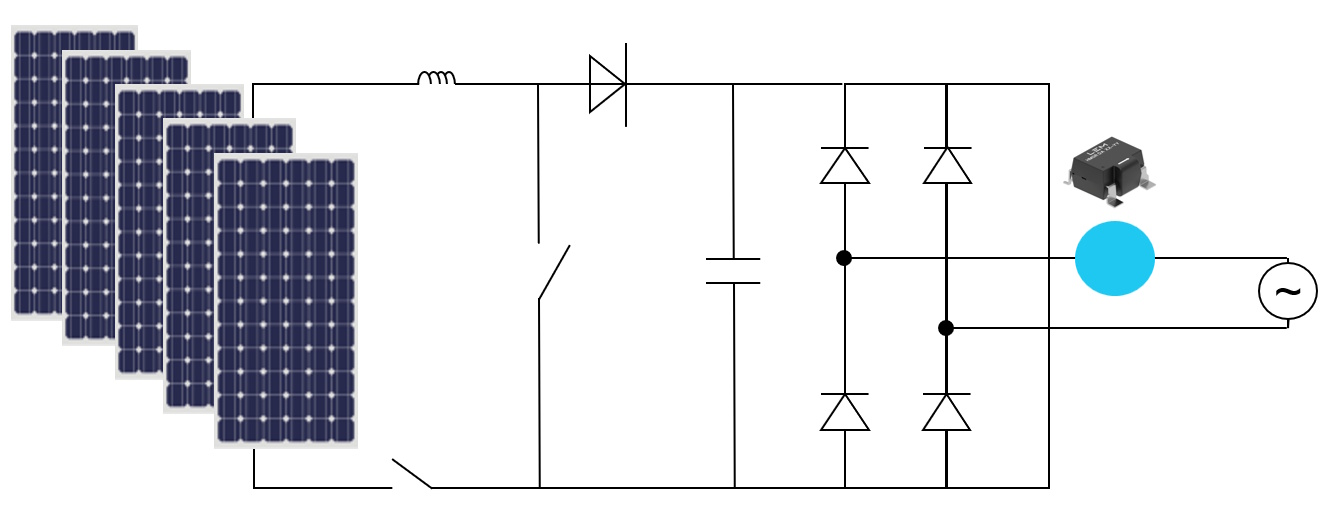

The control loop function in a solar inverter ensures efficient energy conversion and system stability, complying with UL 62109-1 standards

Current Sensor IC: A superior solution for surge protection

While traditional current sensors often require external surge protection and insulation components, ICS technology integrates current measurement with reinforced insulation, providing an all-in-one, compact solution. This integration reduces the system's size, complexity, and cost, while ensuring that it can handle the surge voltages commonly encountered in today’s applications.

Integrated Current Sensors products must meet rigorous insulation standards, such as those outlined in IEC 61000-4-5 (surge immunity tests), and the IEC TS 62993 specifications, which are now extending low voltage (LV) requirements to voltages that were once considered part of the medium voltage (MV) range. As noted by LEM’s experts, even low-voltage standards are now evolving, with surge insulation voltages being pushed higher-up to 10 kV for standard industrial applications and even higher for renewable energy systems.

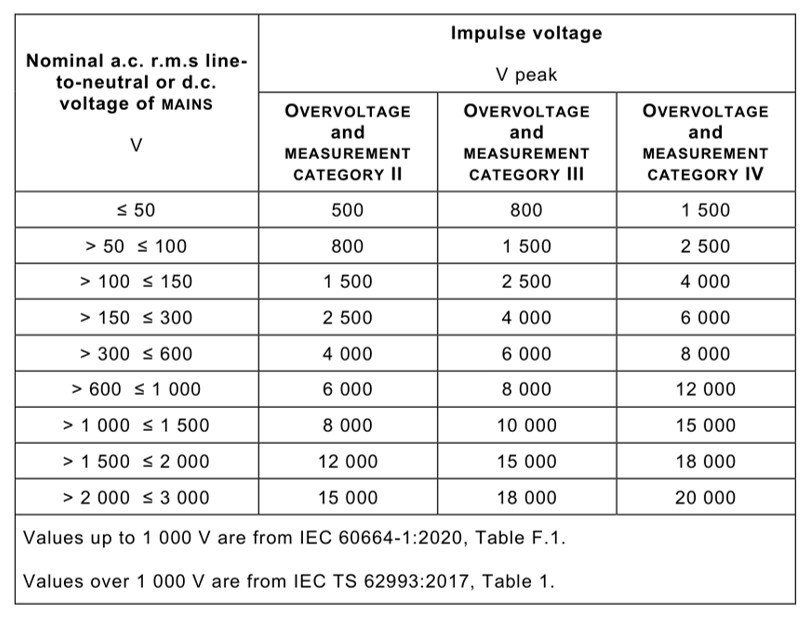

IEC 61010-2-030:2023

Impulse voltages for circuits connected to MAINS

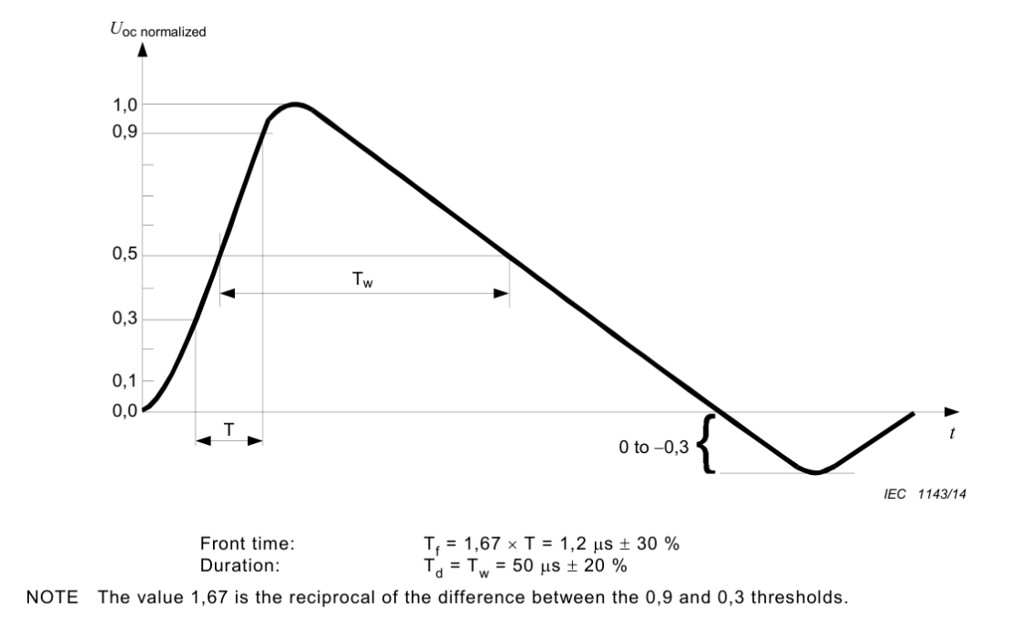

Waveform of open-circuit voltage (1,2/50 µs) at output of the generator with no CDN connected

Key advantages of Current Sensor ICs in “Surge protection”

- Reinforced insulation: ICS sensors feature integrated insulation that can handle surge voltages up to 10 kV or more, as per the latest industry standards. This reinforced insulation ensures the device can withstand even the most extreme voltage spikes without compromising safety or performance.

- Compact design: The combination of current sensing and surge protection into a single unit makes integrated current sensors compact, reducing the need for additional external components. This results in simplified system design and more efficient use of space.

- Improved reliability: Current Sensor IC’s optimized integration of insulation and current sensing ensures that fewer components are needed, reducing failure rates under surge conditions. This leads to enhanced durability and increased reliability, particularly in high-stress environments like electric vehicle powertrains or industrial motor drives.

- Cost efficiency: By eliminating the need for external insulation and surge protection components, Integrated Current Sensor technology reduces both the system's overall cost and its complexity. This offers a significant advantage over traditional systems that rely on multiple external components for surge protection.

Use Cases of Current Sensor ICs for Enhanced Surge Protection

Current Sensor IC technology is particularly beneficial in applications where transient overvoltage and high surge conditions are prevalent. Notable use cases include:

Electric Vehicle (EV) powertrains: The high-voltage environments in EVs, particularly during regenerative braking, demand robust surge protection to safeguard the integrity of the current sensing system.

Industrial Motor Drives: Frequent load changes and electrical noise can cause significant voltage fluctuations. ICS sensors are ideal for ensuring that surge protection is seamlessly integrated into these systems.

Renewable Energy Systems: Solar inverters and other renewable energy equipment are often exposed to lightning-induced surge voltages. Current Sensor ICs technology offers a reliable solution for protecting these systems from high surge conditions, ensuring their continuous operation.

The path forward

As LEM experts pointed out, the future of Integrated Current Sensor technology lies in optimizing existing designs, such as those based on fluxgate sensors. New advancements could include improving the miniaturization of these sensors, using more powerful digital systems (like FPGAs and microcontrollers), and developing overmolded ICS sensors for compact, integrated surge protection.

In the pursuit of higher surge insulation ratings, it is crucial for Current Sensor IC manufacturers to keep pace with evolving industry standards and the increasing demand for higher surge voltage tolerance, especially in sectors like electric vehicles, industrial automation, and renewable energy.