How LEM Drives the Electrification of Long-Haul Transport

Enabling Long-Haul Truck Electrification with Energy Metering

The electrification of long-haul trucking is no longer a distant ambition—it’s a rapidly unfolding reality. With medium- and heavy-duty trucks accounting for 40% of global road transport CO₂ emissions despite representing only 4% of the vehicle fleet, the sector is under pressure to decarbonize.

Europe has responded with bold targets: a 45% reduction in truck emissions by 2030 and 90% by 2040. Achieving these goals requires a coordinated effort across technology, infrastructure, and regulation.

From 2024 onward, tenders have been released throughout Europe to ensure that charging infrastructure can effectively support the rollout of e-trucks on the roads, following the deployment strategy initiated by the Alternative Fuel Infrastructure Regulation (AFIR). This enables hauliers and logistics companies to transition to e-trucks more easily, with Amazon leading the pack when early this year it announced to equip its European fleet with more than 200 long-haul e-trucks – after it had already equipped its fleet in North America with e-trucks for last-mile delivery. Such announcements are likely to follow suit on a larger scale in the near future.

The success of the electrification strategy for heavy-duty vehicles will depend on multiple factors, such as the e-trucks’ total cost of ownership, the deployment of a comprehensive high-power charging infrastructure along travel routes, affordable charging costs, and the evolution of weight allowances for larger batteries in e-trucks. The latter is being proposed by the EU Commission with a review of the Weight and Dimensions Directive (W&D) to raise weight allowance limits by 2 to 4 tons compared to diesel trucks. It is crucial that at this challenging transition phase there’s strong and continuous collaboration between industry, standardization bodies and policymakers.

At the heart of this transformation, LEM plays a pivotal role by delivering trusted energy metering solutions that support the rollout of reliable, scalable charging infrastructure for electric trucks.

Meeting the Demands of E-Truck Charging

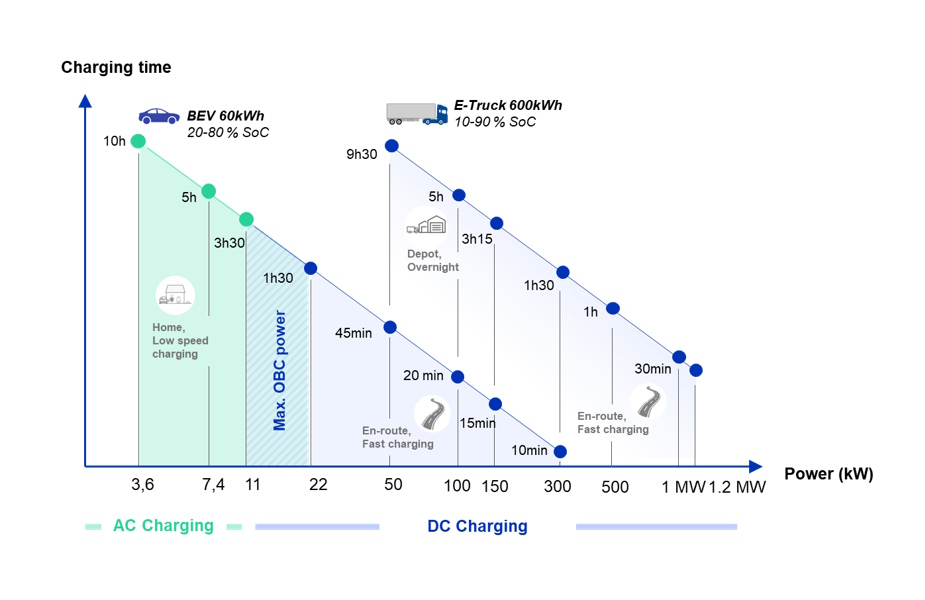

E-trucks, with battery capacities reaching 600 kWh—ten times that of passenger EVs—require robust DC fast-charging solutions. Charging needs vary by use case. Depot charging allows for longer sessions (6–8 hours) at moderate power levels (200–400 kW), where Combined Charging Systems (CCS) are sufficient.

Average time for AC and DC charging

En-route charging, however, is more demanding. EU regulations mandate 45-minute rest breaks every 4.5 hours, creating a narrow window for recharging. Megawatt Charging Systems (MCS), delivering over 1 MW, are essential to meet these needs but introduce challenges such as thermal stress and grid load peaks.

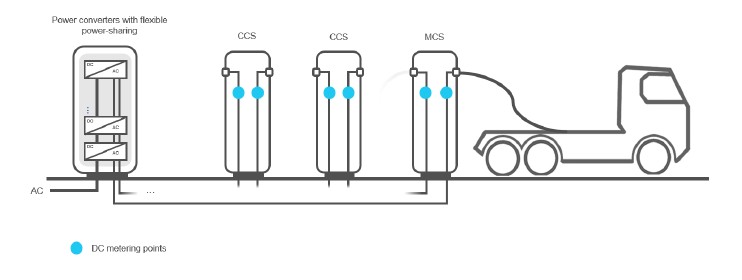

Charging sites typically offer 2–8 MW across multiple CCS and MCS points.

An electric truck charging site combining multiple charging points

Dynamic power sharing is key to optimizing energy distribution and managing infrastructure costs. In this complex ecosystem, accurate energy metering is essential—not just for operational efficiency but for fair and transparent billing.

The role of energy metering solutions in e-truck charging

For all energy charging sessions (in kWh), users must be confident that the energy used by e-trucks is accurately measured and billed. Energy metering enables fairness and transparency for end users and third parties like e-truck owners and charging infrastructure operators. With e-trucks, where the total cost of ownership is particularly sensitive, kWh billing with accurate measurement plays a crucial role in supporting the transition to electrification.

DC energy metering in fast chargers accurately measures the consumed energy, in compliance with laws and regulations. These systems usually compensate for energy losses, like those generated by the charging cables; the metering point is typically located at the e-truck charging inlet for safeguarding.

Legal metrology for energy metering is crucial here, since it guarantees performance and protects end users from potential discrepancies in energy billing. Europe has regulations established for many years, such as the Eichrecht one in Germany, the n° 22.00.570.001.1 in France, as well as the Europe-wide Measuring Instrument Directive (2014/32/EU). North America is not far behind, with regulations like the California/National Type Evaluation Program (CTEP/NTEP).

LEM’s Expertise in DC Energy Metering

LEM has been a pioneer in electrical measurement for over 50 years. Recognizing the emerging needs of EV charging early on, LEM became the first company to develop DC billing meters tailored for fast-charging stations, compliant with European and North American regulations. These meters ensure precise kWh-based billing, a critical factor in managing the total cost of ownership for e-trucks.

LEM’s Direct Current Billing Meters (DCBMs), including the DCBM 400/600 and DCBM 100, are designed for both fast and destination charging. They offer real-time energy monitoring, secure communication with charger controllers, and compliance with key standards such as MID 2014/32/EU, Eichrecht (Germany), and CTEP/NTEP (North America). These meters support charging systems up to 600A and 1000V DC, ensuring accurate billing and seamless integration into complex charging infrastructures.

As well as Eichrecht and the 2014/32/EU MID directive, French regulation n° 22.00.570.001.1, LEM’s DCBMs comply with EN 50470-1:2006, EN 50470-3:2006, PTB-A 50.7, PTB-A 20.1, CISPR32 Class-B emission, IEC 61000-6-2:2016, IEC 61000-6-3:2016, UL 61010-1, CAN/CSA-C22.2 No. 61010-1 and UL94-V0, which makes its DCBMs certified for use across Europe and North America. LEM’s DCBM units are already widely installed across Europe, where they play a crucial role in DC charging.

Supporting Infrastructure Development

As discussed, e-truck charging infrastructure requires unique specifications, ranging from depot to en-route charging, with multiple CCS and MCS charging systems sharing power to satisfy the needs for each use case in an efficient, safe and cost-effective way.

Best-in-class measurement plays a crucial role here, since it is directly linked to cost savings for the e-truck sector; any deviation in measurement accuracy under the demanding conditions of high-power charging results in a deviation in the cost of billed energy.

As charging infrastructure expands, LEM continues to innovate. For depot charging, new communication cable designs support overhead systems, allowing metering sensors to be installed remotely while keeping user interfaces accessible—ideal for both new installations and retrofits.

For high-power en-route charging, LEM’s new DC Energy Sensors (DCES) provide robust, high-precision metering. With current ratings up to 1500A and wide operating temperature ranges (-40°C to +85°C), DCES meters are built for the demanding conditions of MCS applications. They deliver secure, signed energy data for billing, real-time monitoring, and remote updates—ensuring reliability and compliance across diverse charging environments.

Enabling a Sustainable Future

LEM’s expanding portfolio of certified metering solutions is helping lay the foundation for a decarbonized long-haul transport sector. By ensuring accurate, transparent energy measurement, LEM supports fair billing, operational efficiency, and regulatory compliance—key pillars for scaling electric truck infrastructure.

As the industry moves toward electrification, LEM remains a trusted partner, accompanying stakeholders through every phase of the transition. From depot to en-route charging, LEM’s solutions empower operators to build reliable, future-ready infrastructure that supports the global push toward sustainable freight transport.