DC chargers, or Direct Current chargers, are used for charging electric vehicles (EVs). They convert alternating current (AC) from the power grid into direct current that can be used to charge the battery of an EV. The main advantage of DC charging stations is their speed. They can deliver a high-power output, which significantly reduces the charging time compared to AC chargers.

There are two main types of DC chargers: DC fast chargers and DC wall boxes (also known as DC destination chargers). The primary difference between these two lies in their power output and consequently, their charging speed.

DC fast chargers are high-power chargers that can recharge an EV's battery to 80% in around 20-30 minutes. They are typically found in public charging stations and are ideal for long trips where quick charging is essential.

On the other hand, DC wall boxes have a lower power output and are designed for home or office use. They take longer to charge an EV's battery fully, usually several hours, but they are more affordable and convenient for daily charging needs. The choice between a DC fast charger and a DC wall box depends on the specific requirements of the EV user, such as their driving habits, budget, and access to electric vehicle supply equipment.

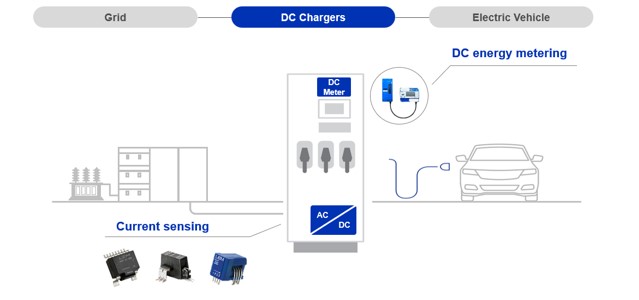

LEM provides solutions for power converters and meters, two functions that are integrated within DC chargers.

What are the functions of a DC Charging Station?

Both DC fast chargers (or direct current fast chargers) and DC destination chargers, serve several essential functions to facilitate rapid charging of electric vehicles.

DC chargers embed the following key functions, being covered by specific standards and regulations depending on regions.

- AC/DC power conversion modules, with a rating between 30-40kW for most of the DC chargers. Up to 6-10 power modules are integrated inside a Direct Current charger.

- The charger controller / HMI manages power modules, facilitates communication with the BEV, and oversees various components within the chargers. Typically, it is linked to a remote backend system, often via 4G or the Internet. This backend system coordinates charging processes with the e-Mobility Service Provider (eMSP), overseeing payments and connecting with end users. Usually one charger controller in integrated per DC charger.

- Insulation monitoring, in charge of the control and monitoring of the insulation of the DC lines, protecting both end users and material.

- DC energy metering is essential for calculating payments based on energy consumed during the charging session. It has become a standard feature in DC chargers, contributing to the transparency of charging across various end users, regardless of the type of BEV being charged.

Measuring current at AC/DC Power module level in DC chargers

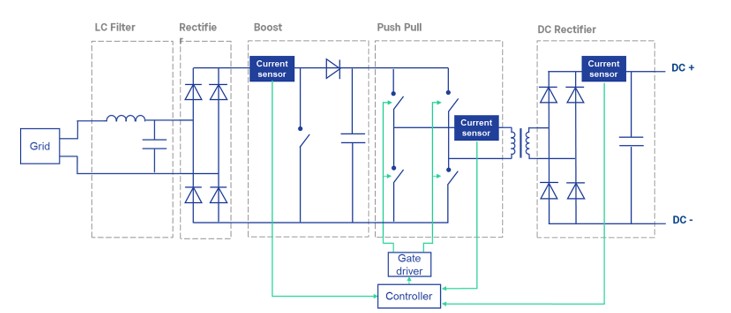

The AC/DC power module in Direct Current chargers serves a crucial role in the charging process of electric vehicles (EVs). This module is responsible for converting the Alternating Current (AC) from the power grid into Direct Current (DC) that the EV's battery can store and use.

The conversion process is vital because while our power grid delivers AC, the batteries in EVs can only store and use power in DC form.

Therefore, the AC/DC power module is an essential component in DC chargers, enabling the efficient and safe charging of electric vehicles by ensuring the correct form of current is delivered to the vehicle's battery.

Power converters are placed in stacks to increase the power of DC fast charging stations, up to 400kW.

In average eight converters are present. In each power module, current sensors are necessary to ensure the control loop function which regulate the stability and the power of inverters.

The current sensing function in AC/DC power modules

DC Chargers, AC/DC Power module current sensors

Within a DC Charger, the control command function of a Power Module AC/DC is ensured by several current sensors. The current sensing function is controlling the AC/DC LLC converters (multiple of 30kW power class) of the EV chargers.

This table below provides LEM current sensors that will fit perfectly in a DC Charging system.

| |||||

|---|---|---|---|---|---|

| Technology | Current Sensor IC | Current Sensor IC | Closed Loop | ||

| Peak Current (current range) | ± 75A | ± 75A | ± 125A | ± 180A | ± 450A |

| Current RMS max | 30A | 30A | 80A | 75A | 200A |

| Output | Voltage | Voltage, ΣΔ | Voltage, ΣΔ | Voltage | Voltage |

| Accuracy @25°C | <1% | <1% | 1% | 0.4% | 0.4% |

| Accuracy -40°C … 85°C | 2.7% | 2.5% | 3% | 1% | 1% |

| Response Time | 2 µs | 2 µs | 2.5 µs | 2.5 µs | 3 µs |

| Bandwidth (-3dB) | 300 kHz | 300 kHz | 400 kHz | 300 kHz | 200 kHz |

| Supply voltage | +5V / 3.3V | +5V / 3.3V | +5V | +5V | +5V |

| Creepage & Clearance (prim/Sec) | 7.5 mm | 8.0 mm | 9.42 mm | 7.5 mm | 12.9 mm |

| Implementation | SOIC 8 or 16 | SOIC 16 | PCBA | PCBA | PCBA / Aperture |

Energy Metering, a key function in DC Charging Stations

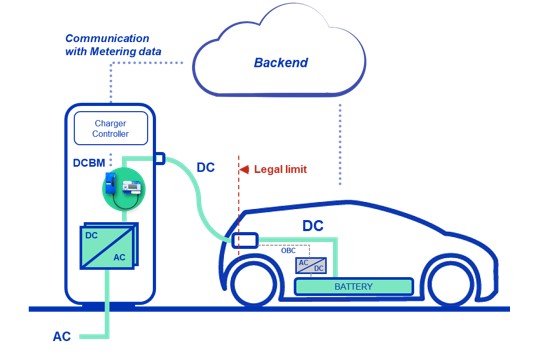

Energy metering plays a pivotal role in DC charging. It is responsible for the accurate billing of charging sessions based on the amount of energy (kWh) consumed. This ensures that EV users are billed correctly for the power they use, promoting transparency and trust between the service provider and the end-user.

Regulation and Performance of energy meters

The process of energy metering is regulated by metrology, the scientific study of measurement.

Metrology sets the standards for energy metering, ensuring accuracy and reliability in the measurements. This regulation is crucial as it guarantees performance and protects end-users from potential discrepancies in energy billing.

The roles of DC Meters in a Direct Current charger for EV

Direct Current meters, or DC meters, are integral to the process of energy metering within DC chargers.

They play several key roles:

- Integration: They ensure compliance with metrology regulations. They are designed and calibrated to meet the stringent standards set by regulatory bodies, ensuring the accuracy of energy measurements.

- Protection: DC meters play a crucial role in protecting user data and charging data. They securely store and transmit data, safeguarding the privacy of users and the integrity of the charging system.

- Display of Information: Meters display information about the charging session, such as the amount of energy consumed, the duration of the charge, and the cost. This information is essential for users to understand their energy usage and costs.

- Monitoring: They allow to monitor the operation of DC fast chargers, tracking parameters like current, voltage, and temperature. This helps in maintaining the performance of the charger and ensuring its safe operation.

DCBM 400/600 integration into a DC Fast Charger for EV

LEM has its own Direct Current Billing Meter product family, solutions for both DC Fast Charging Systems and DC Destination Charging Systems.

Energy Meters for DC Fast Chargers, DC Megawatt Chargers and DC Wall boxes

DCES

The DCES is a DC Metering and monitoring solution up to Megawatt Charging.

- Imax 600 / 1500 A, permanent duty

- Range of operation up to 1000 / 1500 VDC

- Wide temperature range, -40…+85°C

- Metering and monitoring with APIs over RS485

- MID 2014/32/EU and Eichrecht

DCBM 400/600

The DCBM 400/600 is an excellent solution for retrofit and new DC fast charging stations from 25 to 400 kW.

- kWh-based billing in Direct Current fast charging

- Certified by PTB and MID (2014/32/EU), UL Recognized

- 400 A or 600 A, 1000 V DC

- Operating temperature -40 °C … +85 °C (accuracy class B)

- Ethernet HTTP interface easy to integrate, with security

DCBM 100

For DC destination charging applications in the range of 30kW, DCBM 100 will be the energy meter of choice.

- Ready for 800V-platform BEV with V2G

- Compliant with metrology regulations (MID, Eichrecht)

- Accuracy class B, -40°C … +80°C, Imax 80 A, 1000 VDC

- Ethernet HTTP, Plug&Play with Open API profile

- OCMF Readout data

- Monitoring of the DC link

PRODUCT DOCUMENTATION

With the rising demand for electric vehicles, high-performance charging infrastructure is essential. Learn how LEM’s advanced current sensing technologies enhance the efficiency, safety, and reliability of EV Supply Equipment.

Our EV Charging Solutions Brochure provides comprehensive insights into how our solutions can improve your EV charging systems for a more sustainable future.

NEED SUPPORT ON YOUR PROJECT?

You have a project in line with that application and want to discuss it with LEM?

Click on the contact button below and our experts will help you find the best solutions for your needs.