Residual Current Monitoring Challenges in EVs AC Charging Applications

From Uni-directional AC Charging to the Challenges of Bi-directional and Vehicle-to-Everything Applications.

The Growing Need for RCM in EV Charging

The infrastructure for electric vehicles (EVs) is evolving, with the market for AC wallboxes growing quickly.

At the same time, new challenges are emerging, particularly within the EV, due to the rise of bi-directional charging and Vehicle to Everything (V2X) applications. These trends mean that residual current monitoring (RCM) is taking center stage in AC charging applications.

This article delves into the current market, emerging trends, and the importance of residual current monitoring, in both the wallbox and the EV, to ensure compliance with regulations and safety standards, while enabling a competitive time to market.

AC Charging Market Maturity and Emerging Trends

The AC wallbox and cable markets have seen substantial growth, driven by the increasing adoption of electric vehicles worldwide. These markets have rapidly matured and are characterized by well-defined specifications and stringent standards that ensure the safety and efficiency of EV AC charging.

New challenges, however, are arising within the EV itself.

First, the transformerless on-board charger (OBC) is the next big AC charging trend, because car makers need to decrease weight and volume, as well as improve the efficiency of every system in an EV while still controlling cost when producing in high volumes. These performance requirements and safety challenges due to the high voltages and currents mean that RCM is an increasingly important part of the system.

The second challenge is the new layers of complexity due to the introduction of Vehicle to Everything (V2X) technology. V2X allows the energy stored in EV batteries to feed other vehicles, homes, appliances and even the grid, and not just to power the vehicle. This paradigm shift has significant implications for the design and operation of EV charging infrastructure as well as on-board charging circuitry/systems. Bi-directional OBC systems are essential for enabling V2X capabilities, and these systems require advanced safety solutions to protect EV end-users from electric shock. Bi-directional OBCs require exceptionally reliable and accurate RCM solutions that can handle both AC and DC currents while complying with the latest regulations, such as ISO5474.

Overcoming Safety Issues in EV Charging Systems

The primary concern in EV charging is ensuring the safety of users against electrical shock. Traditional AC charging infrastructure has robust standards and clear specifications. Within the EV, the transition to transformerless and bi-directional OBC systems, however, introduces complexities that demand higher standards of residual current detection. Specifically, RCM sensors need to be immune to environmental magnetic and electric fields, manage overloads efficiently, and avoid false tripping that disrupts the charging process.

RCM sensors play a critical role in protecting users from electric shock by detecting leakage currents and triggering protective mechanisms. In EV charging applications, the requirements are particularly stringent. They need to detect both AC and DC leakage currents and must be highly robust to avoid false alerts, which can interrupt the charging process.

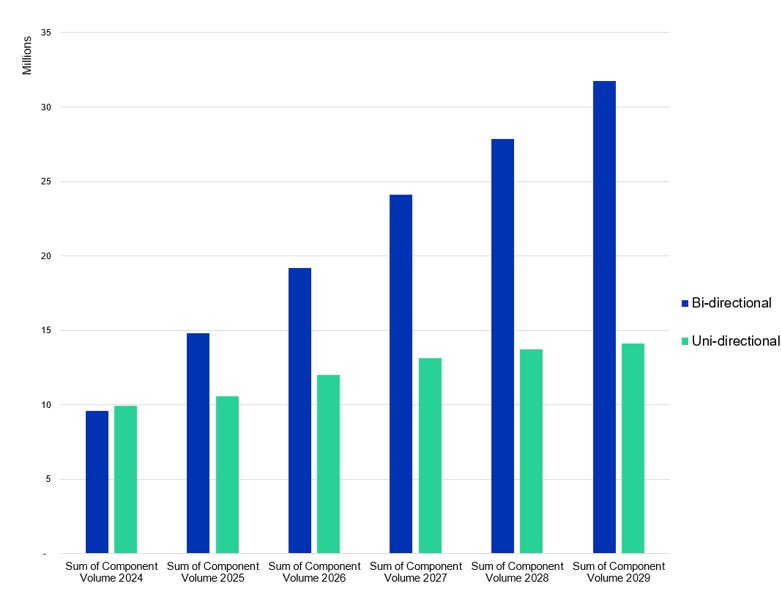

Fig. 1: OBC market evolution towards bidirectional

The emergence of bi-directional OBC systems (Fig.1) adds another layer of complexity. These systems must comply with the new ISO5474 norm, which specifies functional safety requirements for AC power transfer in electric vehicles. RCM sensors used in bi-directional OBC systems must be compliant with this standard, which mandates the detection of AC and DC leakage currents with high accuracy to ensure safety during V2X operations.

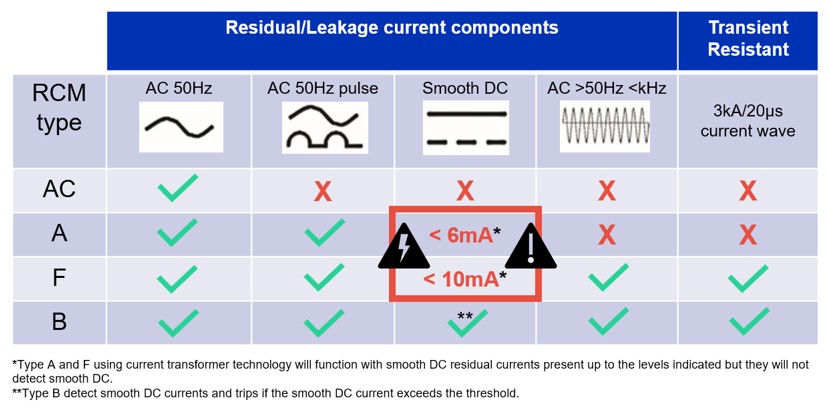

IEC 62752, UL2231, IEC62955, and the new ISO5474 require detection of AC and smooth DC leakages. As shown on Fig.2, you cannot use any RCM solution as leakage current detection components of type AC, A and F cannot ensure the right level of safety, only a type B can measure and detect AC and smooth DC.

Fig. 2: An RCM type B detects AC and smooth DC

Cutting-Edge Residual Current Monitoring Solutions

Fluxgate technology provides superior performance in detecting both AC and DC leakage currents, making it a preferred choice for residual current monitoring in EV charging applications. LEM’s RCM sensors, the CDSR and CDT series, benefit from the company’s unique fluxgate technology, enabling outstanding accuracy and bandwidth.

It is also important to ensure the RCM sensors are functioning correctly, so the CDSR and CDT families offer built-in self-test and diagnostics (temperature, over-current detection, over/under voltage protection, etc.). LEM’s dedication to quality and innovation, as well as their commitment to compliance with international standards, sets industry benchmarks and makes its solutions appealing to automotive engineers for EV charging and other applications.

AC Wallbox and Charging Cables

The ideal current sensors for AC wallbox designs must be compliant with international tripping standards (IEC 62752/62955/UL 2231) and suitable for a wide range of output power levels, as well as supporting single and three-phase architectures, to allow the reuse of designs across 3.3 kW to 22 kW AC charging systems.

The fluxgate technology developed by LEM is the most accurate contactless measurement technology available today, and allows CDSR sensors to offer exceptional accuracy when monitoring both AC and DC and enables the capability of detecting leakage as low as 5 mA. The sensors are available in single and three-phase versions, making them suitable for various charging systems. Their compact design and easy integration, as well as their vertical shape, streamline the design process for system engineers and make them an ideal choice for OEMs and tier-one suppliers looking to enhance the safety and performance of their AC wallbox solutions.

The recently launched CDT sensor is also based on LEM’s patented fluxgate technology and stands out as a solution to detect leakage in charging cables, with its unprecedented accuracy of ±0.5 mA @ 5 mA and best-in-class automotive grade. The CDT offers dynamic fault tripping and advanced diagnostic functions, while meeting all relevant standards, easing the design process for system engineers.

The CDT sensor is available in single and three-phase versions, making it suitable for various charging cable configurations. Its advanced diagnostic functions and dynamic fault-tripping capabilities provide system engineers with valuable tools to optimize the performance and safety of their charging solutions.

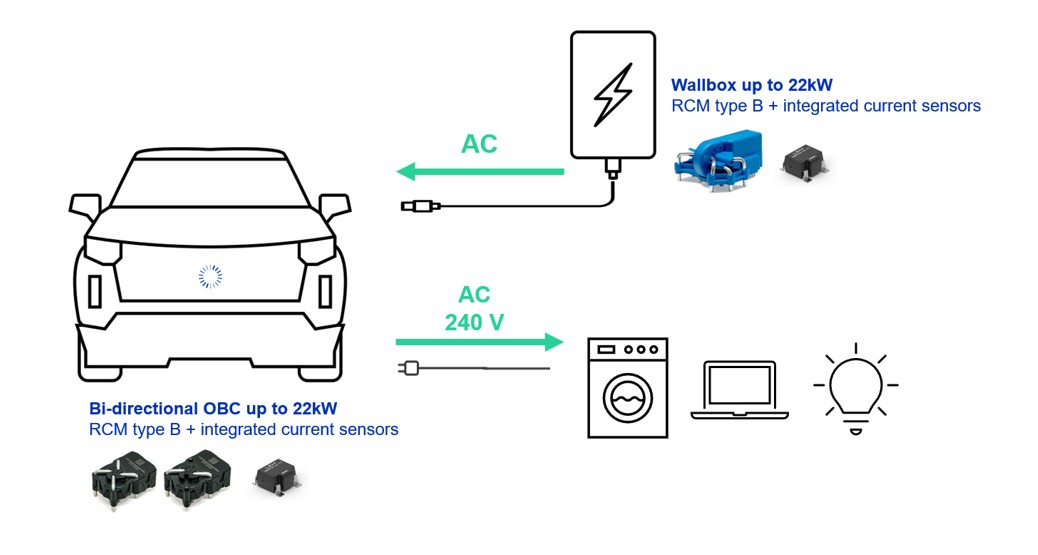

The shift to Transformerless and bi-directional On-Board Charging (OBC) Systems

The shift towards bi-directional OBC systems, allowing the use of EV batteries as power sources for various applications (V2X), underscores the need for automotive-grade, type B RCM sensors with ISO 26262 ASIL B compliance and adherence to the new ISO5474 norm. LEM’s CDT-SF sensor meets all of these requirements and offers dual independent measurement channels, self-diagnostic capabilities, the breakthrough level of accuracy described above and detailed error reporting via SPI. Its dual independent measurement channels provide redundancy and enhance reliability, while its self-diagnostic capabilities and detailed error reporting ensure optimal performance and safety. The sensor also allows fully external test winding for safety tests and more.

The dynamic tripping feature allows system engineers to set the tripping threshold according to specific regional and normative requirements. This flexibility ensures that the sensor can be used in various markets and applications, and can also be used to adapt the system and improve efficiency when switching from vehicle-to-load (V2L) charging to vehicle-to-grid (V2G) charging.

Fig. 3: LEM solutions for EV AC applications

Leading the Future of EV Charging Safety

In the rapidly evolving world of EV AC charging, LEM continues to lead with its innovative RCM solutions (Fig.3). By addressing the nuanced challenges of bi-directional and V2X applications and ensuring compliance with the latest norms, LEM provides system engineers with reliable, high-quality sensors that simplify design processes and enhance safety. As the market progresses, LEM remains a pivotal player, driving advancements and setting benchmarks in electrical measurement technology.

With the increasing adoption of electric vehicles and the growing complexity of AC charging applications the need for advanced residual current monitoring solutions has never been greater. LEM's CDSR and CDT sensors provide system engineers with the tools they need to ensure the safety and performance of their charging solutions, while the CDT-SF sensor addresses the unique challenges of bi-directional OBC systems and V2X applications. As the industry continues to evolve, LEM's commitment to innovation and excellence will ensure that it remains at the forefront of electrical measurement technology, providing reliable and accurate solutions for the future of EV charging.