AC chargers, or Alternating Current chargers, are used for charging electric vehicles (EVs).

They take the AC electricity from the home or office power supply and feed it into the vehicle's onboard charger, which then converts this AC power into Direct Current (DC) to charge the battery of the EV.

The main advantage of AC charging stations is that they can be installed in homes or workplaces, allowing EV owners to charge their vehicles overnight or during work hours.

However, due to the lower power output compared to DC chargers, AC chargers typically take longer to fully charge an EV's battery, often several hours depending on the battery capacity and the power rating of the charger.

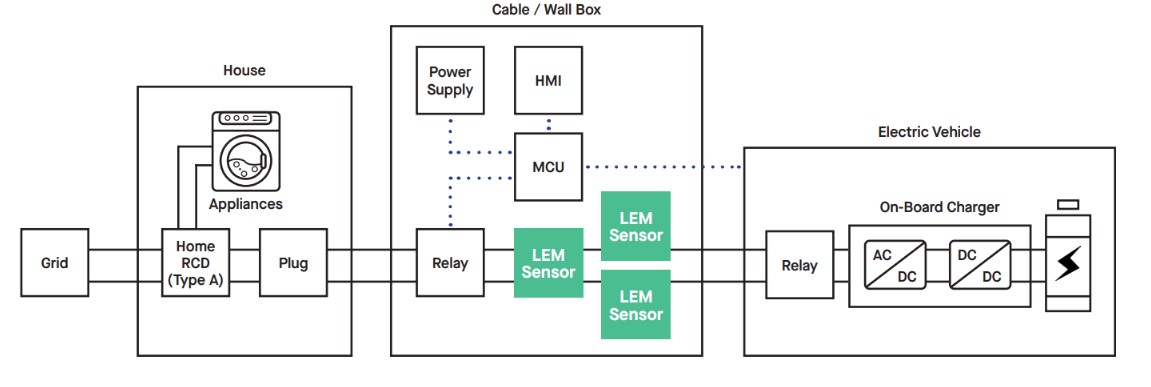

In AC charging systems, current sensors are needed for 2 purposes: measure output current and detect leakages.

Why are Leakage Current Sensors so important in AC Chargers?

In AC chargers, the incorporation of DC leakage current sensors (also known as Residual Current Sensors) is crucial for ensuring the safety and efficiency of the charging process.

DC leakage current refers to the unintentional flow of direct current to the ground, which can pose serious risks if not properly monitored. A DC leakage current sensor plays a pivotal role in detecting and measuring such currents, offering a proactive approach to identify potential faults and mitigate safety hazards.

By providing real-time monitoring, these sensors contribute to the reliability and safety of AC chargers and wall boxes, aligning with the highest standards of electrical safety in EVSE.

Addressing the "Blinding Effect" of RCD Type A: Leveraging RCD Type B

The "blinding effect" of Residual Current Devices (RCD) Type A can be a significant concern in AC charging stations, particularly when these devices are subjected to high-frequency DC leakage currents. The blinding effect occurs when the RCD Type A incorrectly interprets DC leakage as normal AC current, rendering it less effective in detecting actual faults. To counter this, deactivating electrical home protection is not a recommended solution due to compromising overall safety.

Instead, opting for Residual Current Devices Type B provides a viable solution. RCD Type B is designed to accurately detect both AC and DC residual currents, eliminating the blinding effect associated with RCD Type A. This ensures that the RCD remains effective in safeguarding against electrical faults, offering enhanced protection for users and the electrical vehicle supply equipment.

LEM sensors ensure the safety and reliability of the AC charger

LEM offers advanced solutions that seamlessly integrate into AC chargers, addressing critical safety issues. The inclusion of a CDSR DC leakage current sensor ensures that potential faults are promptly identified, enhancing the overall safety of the charging system.

CDSR Series

- RCD type B measuring levels

- Primary current 32 A RMS

- 150 ± mA AC and DC measuring range

- ±0.5 mA accuracy at 5 mA AC and DC

- DC to 2kHz Bandwidth

Simultaneously, LEM's current sensor technology facilitates the precise measurement of output current, contributing to the efficient operation of AC chargers. Curent Sensor IC and the CKSR product family are the components of choice to measure the output current of AC Chargers.

With LEM's expertise in current sensing and monitoring solutions, users can confidently deploy AC chargers with a robust safety framework. By combining leakage current sensors and accurate current measurement, LEM empowers AC charger manufacturers to meet and exceed safety standards, providing reliable and secure charging solutions for electric vehicles.

AC Chargers, Wallboxes, Charging cables current sensors

AC charging stations require to be equipped with accurate components. LEM's current sensors, renowned for their precision, stand as the solution to ensure the exact measurement of output current.

This table below provides LEM current sensors that will fit perfectly in an AC Charging system.

| ||||

|---|---|---|---|---|

| Technology | Current Sensor IC | Current Sensor IC | ||

| Peak Current (current range) | ± 75A | ± 75A | ± 125A | ± 180A |

| Current RMS max | 30A | 30A | 80A | 75A |

| Output | Voltage | Voltage, ΣΔ | Voltage, ΣΔ | Voltage |

| Accuracy @25°C | <1% | <1% | 1% | 0.4% |

| Accuracy -40°C … 85°C | 2.7% | 2.5% | 3% | 1% |

| Response Time | 2 µs | 2 µs | 2.5 µs | 2.5 µs |

| Bandwidth (-3dB) | 300 kHz | 300 kHz | 400 kHz | 300 kHz |

| Supply voltage | +5V / 3.3V | +5V / 3.3V | +5V | +5V |

| Creepage & Clearance (prim/Sec) | 7.5 mm | 8.0 mm | 9.42 mm | 7.5 mm |

| Implementation | SOIC 8 or 16 | SOIC 16 | PCBA | PCBA |

PRODUCT DOCUMENTATION

As the popularity of electric vehicles increases, the need for robust charging infrastructure becomes more critical. Explore how LEM’s cutting-edge current sensing technologies can boost the efficiency, safety, and reliability of EV Supply Equipment.

Our EV Charging Solutions Brochure offers detailed insights into how our innovative solutions can enhance your EV charging systems for a greener future.

NEED SUPPORT ON YOUR PROJECT?

You have a project in line with that application and want to discuss it with LEM?

Click on the contact button below and our experts will help you find the best solutions for your needs.